Inquiry

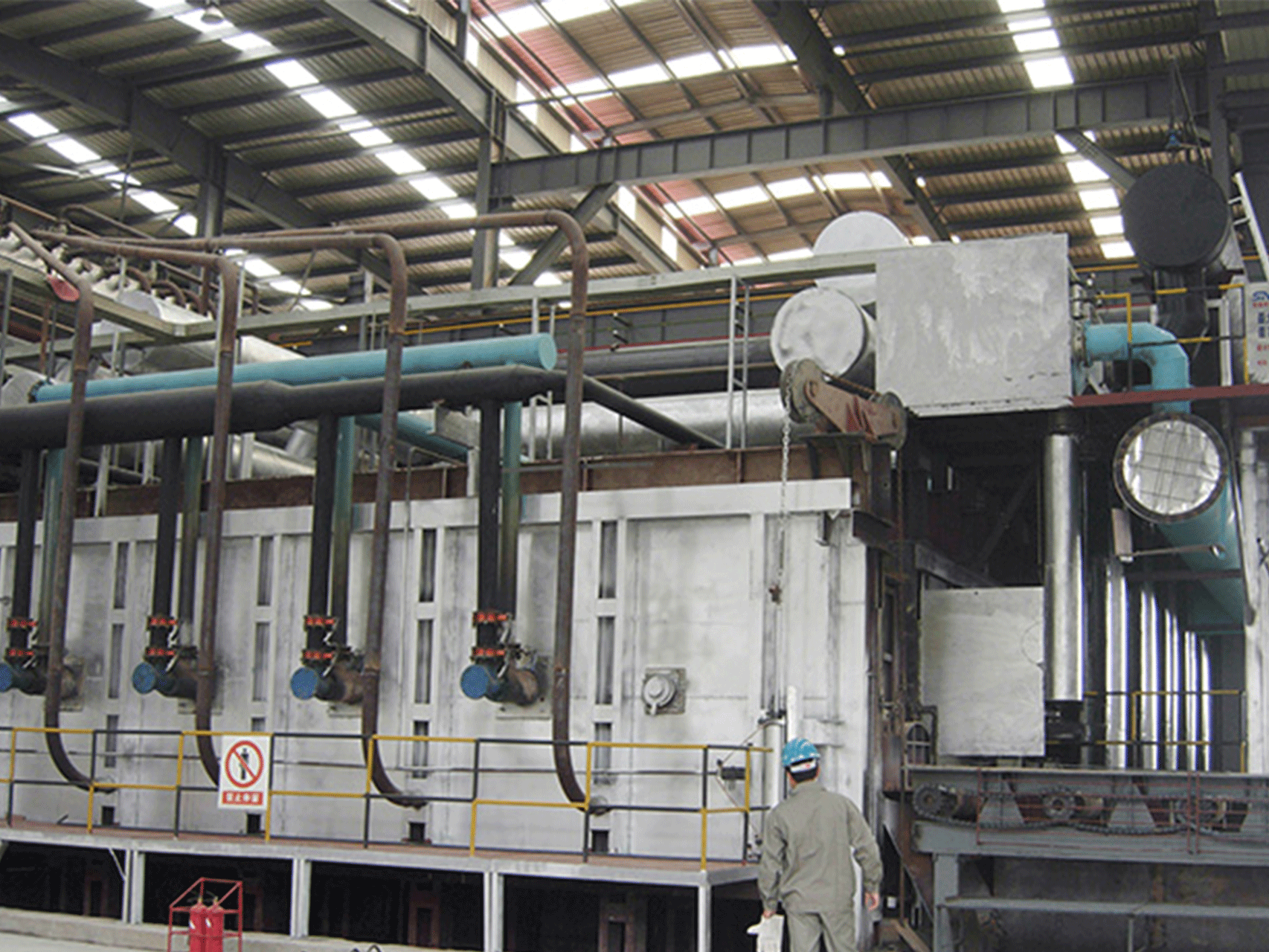

Coal Gas Furnace

A coal gas furnace is a type of industrial furnace that burns coal to produce a gas that is used as fuel for heating and other industrial processes. Coal gas furnaces were commonly used in the 19th and early 20th centuries before the widespread adoption of natural gas.

In a coal gas furnace, coal is burned in a combustion chamber to produce a gas mixture of hydrogen, carbon monoxide, and other gases. This gas mixture is then piped to the area where it is needed for heating or other industrial processes. Coal gas furnaces can produce high temperatures and provide heat for large industrial processes.

However, coal gas furnaces have fallen out of favor due to their high emissions of sulfur dioxide and particulate matter. The use of coal gas furnaces has largely been replaced by cleaner-burning fuels such as natural gas, propane, and electricity.

Advantages of Coal Gas Furnace

While coal gas furnaces are no longer commonly used due to their environmental impacts, there were some advantages to using them in the past, including:

- Low cost: Coal was historically a relatively cheap fuel source, making coal gas furnaces an affordable option for industrial heating.

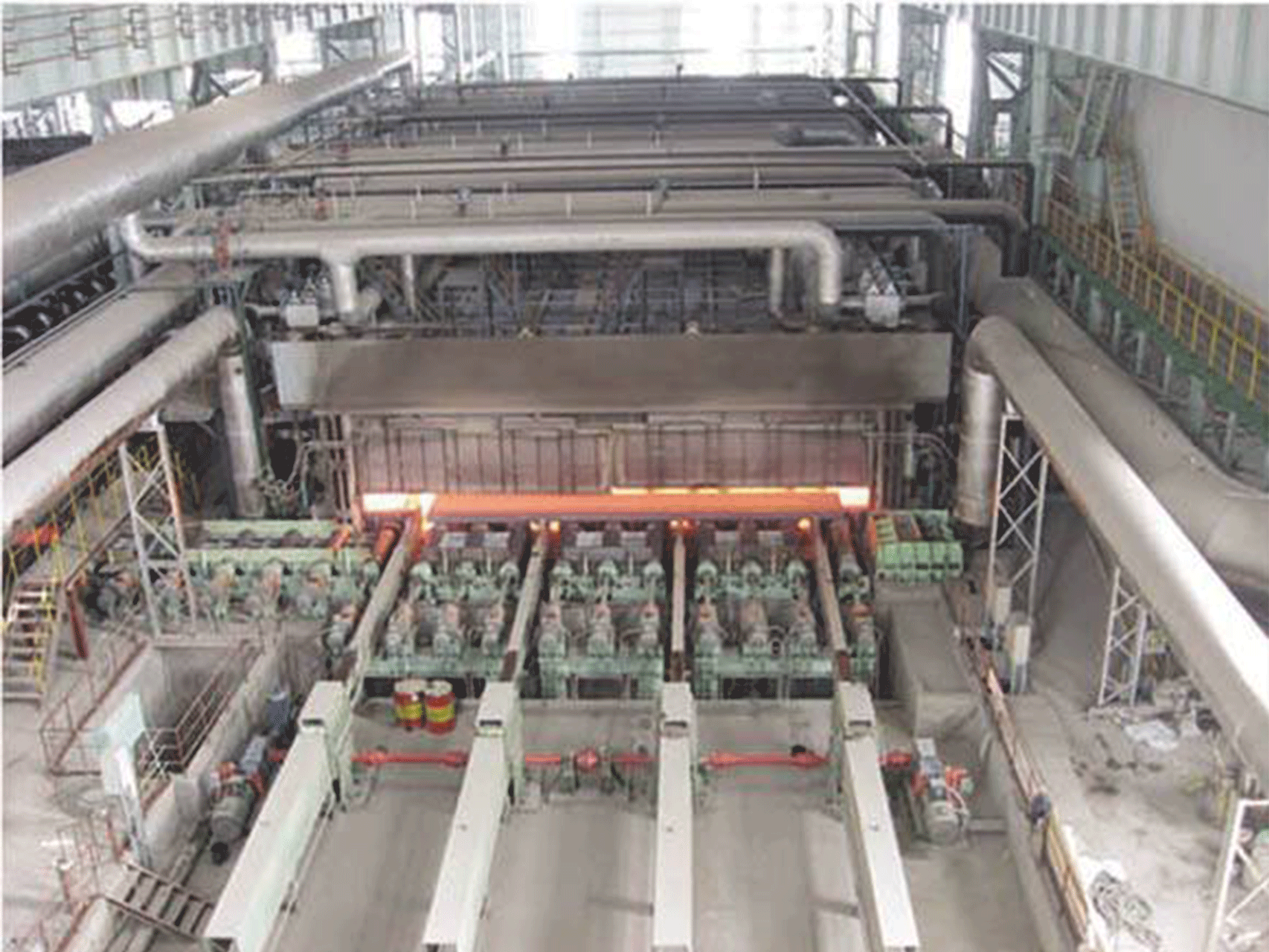

- High heat output: Coal gas furnaces could produce high temperatures, making them suitable for large-scale industrial processes.

- Accessibility: Coal deposits are widely available in many parts of the world, making coal gas furnaces a readily available option for industrial heating in areas without access to other fuels.

- Versatility: Coal gas could be used for a variety of industrial applications, including heating, lighting, and power generation.

Coal Gas Furnace FQA

Q: How does a coal gas furnace work?

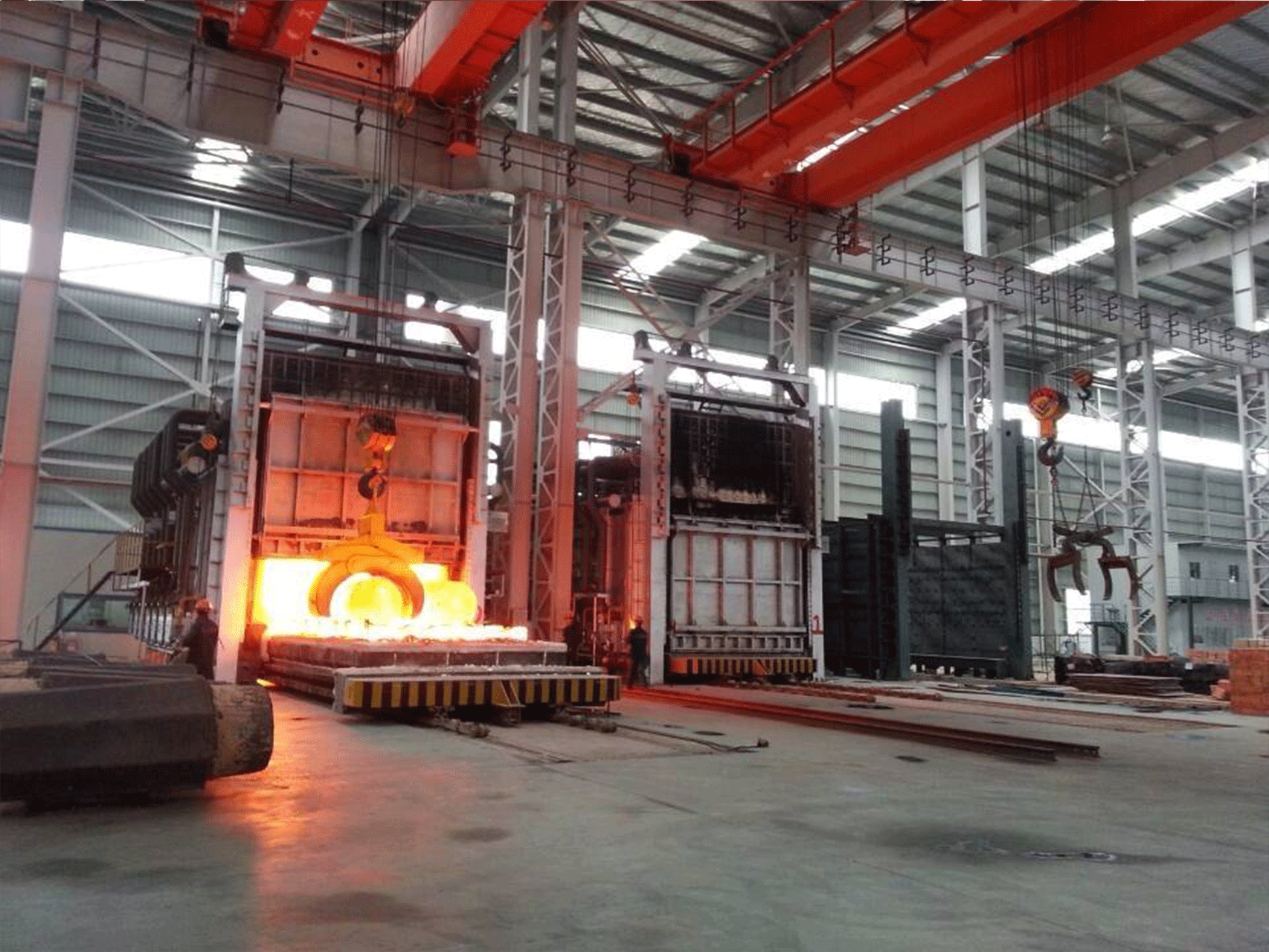

A: A coal gas furnace is an industrial furnace that burns coal to produce a gas that is used as fuel for heating or other industrial processes. The process of producing coal gas involves several steps:

- Coal is heated in an enclosed chamber to drive off volatile compounds, producing a gas mixture of hydrogen, carbon monoxide, and other gases.

- The gas mixture is then cooled and scrubbed to remove impurities such as sulfur and tar.

- The resulting gas is piped to the area where it is needed for heating or other industrial processes.

- The gas is burned in a combustion chamber, producing heat and releasing carbon dioxide and water vapor as byproducts.

- The heat generated by the combustion is then transferred to the area being heated or used for industrial processes.

Modern coal gas furnaces typically use more advanced technologies, such as fluidized bed combustion or gasification, to improve efficiency and reduce emissions of pollutants.

Q: Are coal gas furnaces safe to use?

A: Coal gas furnaces can pose safety risks if not operated and maintained properly. Some of the safety concerns associated with coal gas furnaces include:

- Fire and explosion hazards: Coal gas is highly flammable and can pose a risk of fire and explosion if not handled and stored properly.

- Carbon monoxide poisoning: Coal gas furnaces can produce carbon monoxide, a colorless and odorless gas that can be deadly if inhaled in high concentrations.

- Air pollution: Burning coal can release pollutants such as sulfur dioxide, nitrogen oxides, and particulate matter, which can have negative impacts on air quality and human health.

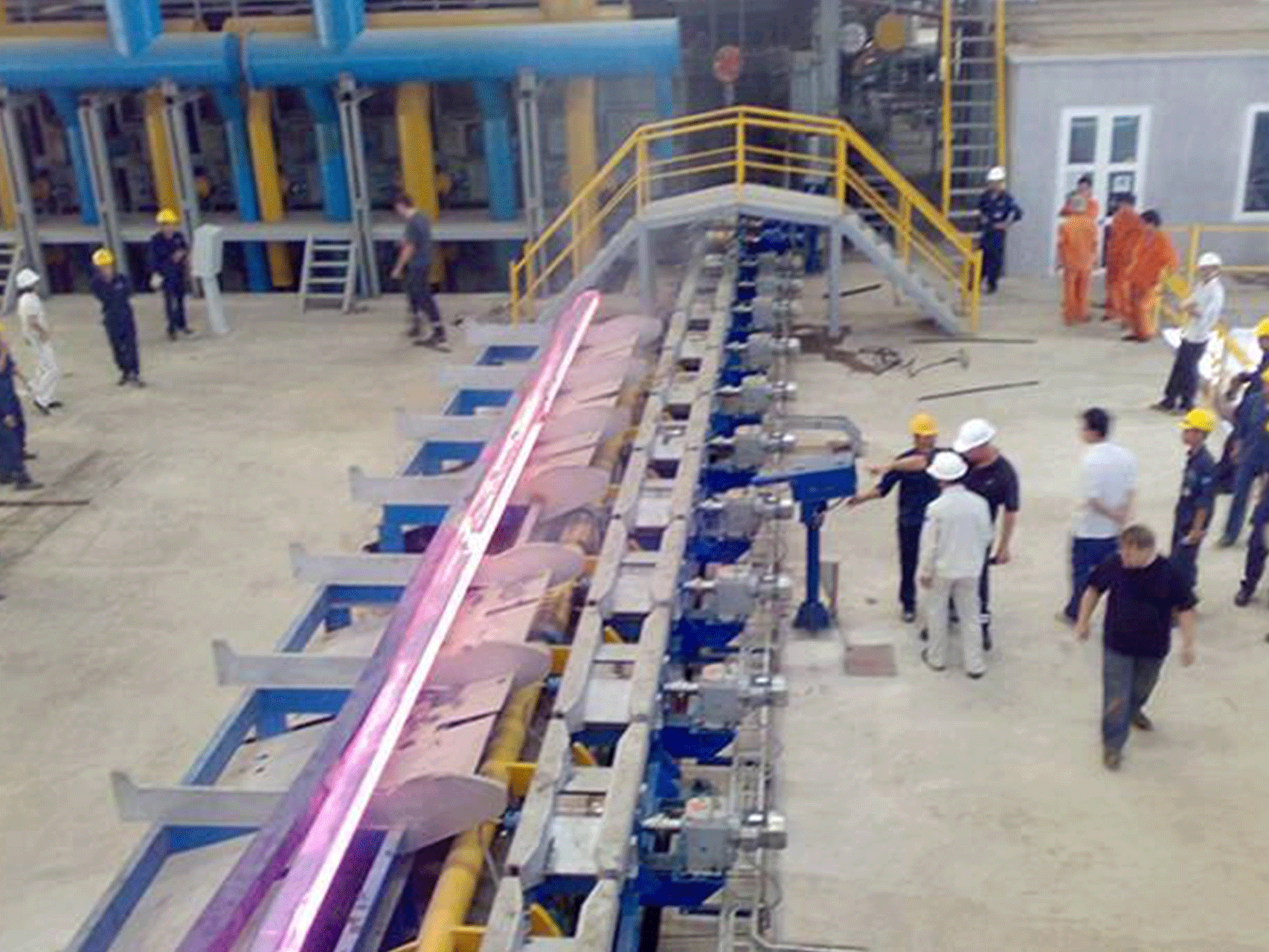

- Occupational hazards: Workers who operate and maintain coal gas furnaces may be exposed to hazardous conditions such as high temperatures, toxic gases, and moving machinery.

Q: How efficient are coal gas furnaces?

A: Coal gas furnaces are generally less efficient than modern heating systems that use natural gas, propane, or electricity. This is because coal gas production involves several steps, including the heating and cooling of the coal, which results in energy losses. Additionally, burning coal gas releases more greenhouse gases and other pollutants than burning natural gas or propane, making them a less environmentally-friendly option for heating.

Due to the environmental impacts of coal gas production and burning, and the availability of cleaner and more efficient fuel sources, coal gas furnaces are not typically used in residential homes. In the past, coal gas was used for home heating and lighting, but this practice was largely phased out in the mid-20th century due to safety and environmental concerns.

Q: Can coal gas furnaces be used in residential homes?

A: Today, most residential heating systems use natural gas, propane, electricity, or other clean energy sources. These modern heating systems are typically more efficient and produce fewer greenhouse gases and other pollutants than coal gas furnaces, making them a more sustainable and environmentally-friendly option for home heating.

Q: Are coal gas furnaces still in use today?

A: The use of coal gas furnaces has declined significantly over the past century due to concerns about their environmental impact and safety risks. In many countries, coal gas has been largely replaced by natural gas, propane, and electricity for heating and other industrial applications. However, there are still some industrial processes and applications that continue to use coal gas or similar fuels produced from coal. These processes may include applications such as steel production, chemical synthesis, and power generation. In some cases, modern coal gasification technologies can be used to improve efficiency and reduce emissions of pollutants. It's important to note that the use of coal gas for heating and other applications has declined significantly due to its negative environmental and health impacts. Many countries have adopted policies and regulations to phase out the use of coal and other fossil fuels in favor of cleaner and more sustainable energy sources.