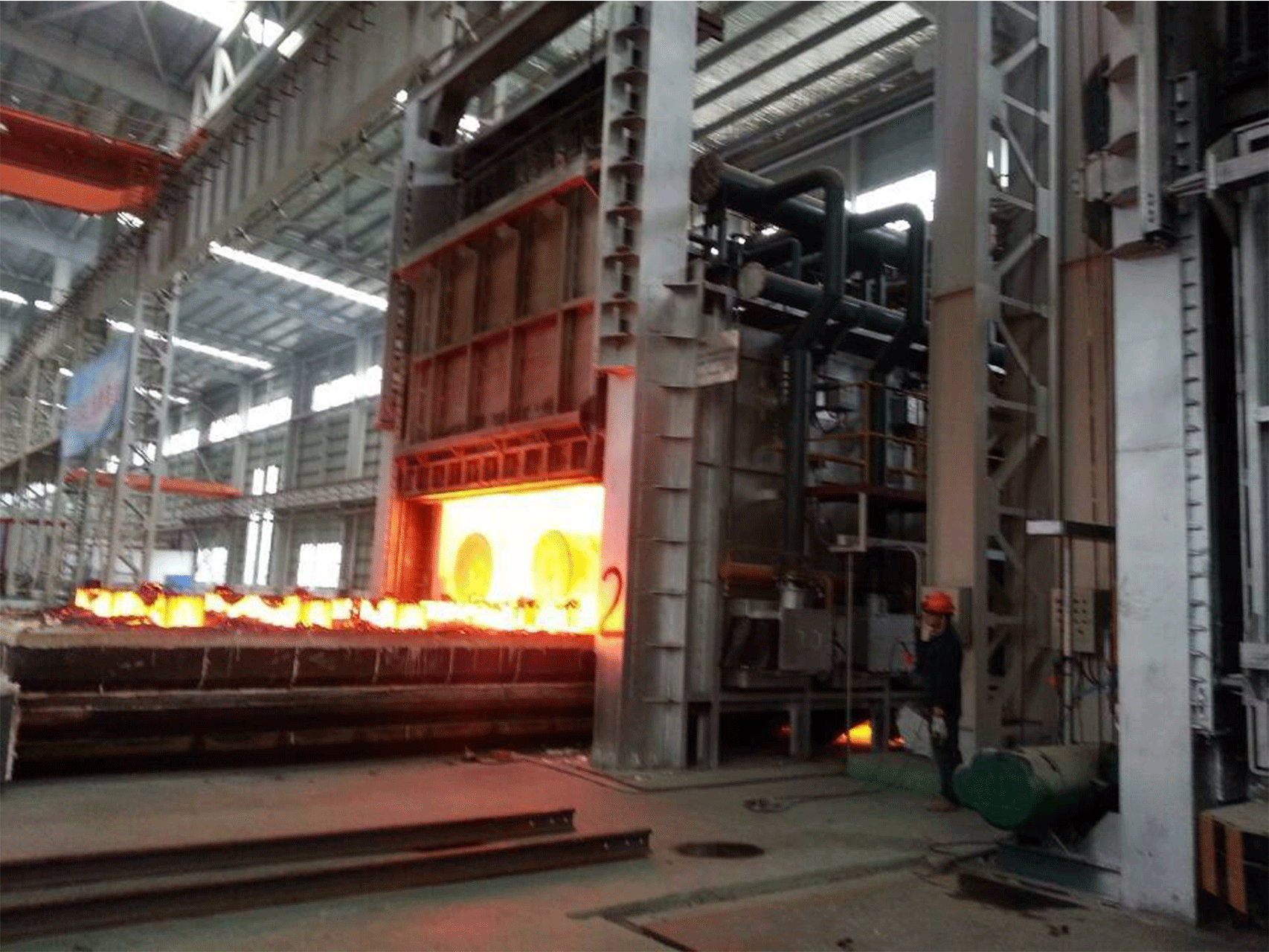

A Regenerative Reheating Furnace is a type of high-efficiency industrial furnace used for high-temperature heat treatment processes such as annealing, hardening, and tempering of metal components. It operates on the principle of regenerative heat exchange, which captures waste heat from exhaust gases and reuses it to preheat incoming combustion air—resulting in substantial energy savings and lower emissions.

These furnaces are commonly used in the steel, aluminum, and automotive industries, where precise temperature control, uniform heating, and energy efficiency are essential.

Structure of the Regenerative Reheating Furnace

A typical Regenerative Reheating Furnace includes the following components:

- Combustion Chamber: The core of the furnace, where fuel is burned to generate high temperatures for the heat treatment process.

- Regenerator: A key system for thermal energy recovery. It consists of refractory-lined chambers filled with ceramic materials that absorb and store waste heat from exhaust gases.

- Heat Recovery System: A network of ducts and valves that control the direction and flow of hot gases and combustion air through the regenerator.

How It Works:

- Heating Cycle: The operator sets the required temperature and combustion rate. Combustion air passes through the hot regenerator, absorbing stored heat before entering the combustion chamber. This preheated air mixes with fuel and is ignited to create high-temperature flames.

- Cooling Cycle: After combustion, hot exhaust gases are routed through the regenerator, where they transfer residual heat to the ceramic media. The stored heat is then used in the next cycle, dramatically reducing fuel use.

Working Principle of Regenerative Reheating Furnace

The Regenerative Reheating Furnace operates through a continuous cycle of heat generation and recovery. The main steps include:

-

Combustion: Natural gas or oil is burned in the combustion chamber, producing the high heat needed for metal processing.

-

Exhaust Heat Recovery: Hot gases are directed through the regenerator, where ceramic media absorb and store thermal energy.

-

Air Preheating: In the next cycle, incoming combustion air is routed through the hot regenerator, picking up stored heat before entering the burner. This significantly reduces the fuel required for ignition.

-

Reversal Cycle: The system periodically reverses airflow so both regenerators alternately absorb and release heat.

-

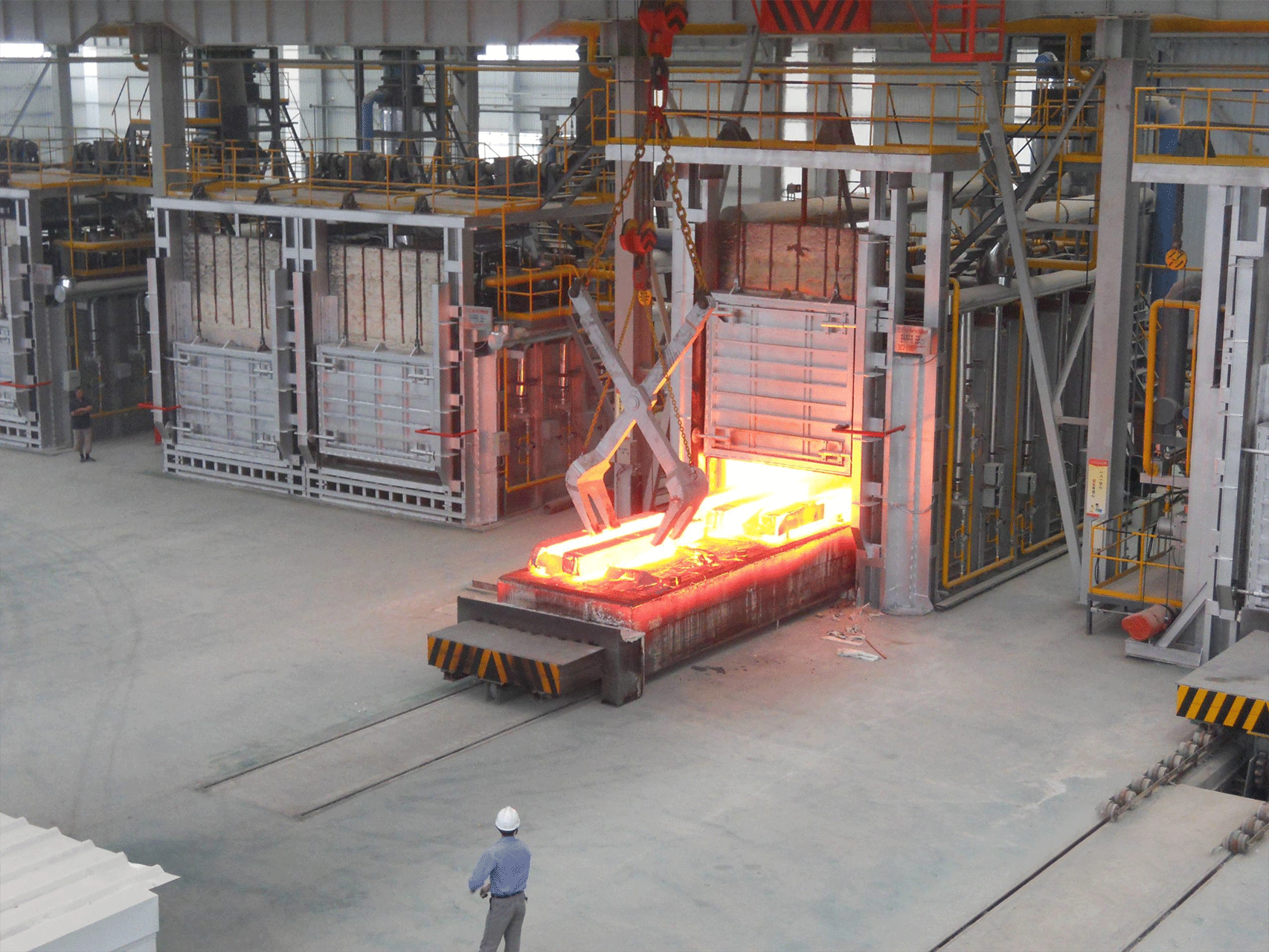

Material Handling: Metal parts are moved through the furnace using roller hearths, conveyors, or walking beams, ensuring uniform exposure to heat and temperature gradients.

Function of Regenerative Reheating Furnace

The primary function of a Regenerative Reheating Furnace is to provide controlled, high-temperature heating for metal parts before forging, rolling, or other processes. It achieves this through:

-

Efficient Combustion: By mixing fuel with preheated air, combustion is more complete and energy loss is minimized.

-

Heat Recovery: Captures and reuses exhaust heat, enhancing thermal efficiency.

-

Accurate Temperature Control: Advanced control systems regulate temperature zones to match process specifications.

-

Cooling System: Components are cooled after treatment using air or water, depending on process needs.

Scope of Application

Regenerative Reheating Furnaces are suitable for a wide range of heat treatment and reheating applications, including:

Steel Manufacturing

Used for reheating billets, slabs, bars, and coils for processes like hot rolling, forging, annealing, and tempering.

Aluminum Manufacturing

Ideal for solution annealing, aging, and stress relief of aluminum sheets, coils, and extrusions.

Automotive Industry

Used in the heat treatment of precision components such as gears, axles, engine parts, and bearings that demand tight thermal tolerances.

Key Advantages of Regenerative Reheating Furnaces

-

Superior Energy Efficiency

Recovers waste heat to preheat combustion air, reducing fuel use and lowering operational costs. -

Uniform Heating

Provides consistent temperature across all material surfaces, reducing defects and improving product quality. -

Precise Temperature Control

Advanced automation ensures stable temperature profiles critical for metallurgical consistency. -

Environmentally Friendly

Lower energy consumption means fewer greenhouse gas emissions and improved sustainability. -

High Throughput and Productivity

Capable of operating at temperatures up to 1,500°C with rapid heating cycles and efficient recovery, increasing output.