Industrial electric furnaces are pivotal in modern manufacturing, delivering precise, efficient, and sustainable heat treatment solutions for materials like metals, alloys, and ceramics. Unlike traditional fuel-fired furnaces, electric furnaces use electricity to achieve high temperatures, offering cleaner operation and superior control. Jiangsu Yinuo Thermal Energy Technology Co., Ltd., based in Xuzhou, China, is a global leader in manufacturing advanced industrial electric furnaces. This guide explores the technology, applications, and advantages of these furnaces, showcasing why Jiangsu Yinuo is a trusted partner for industries worldwide.

The Role of Industrial Electric Furnaces

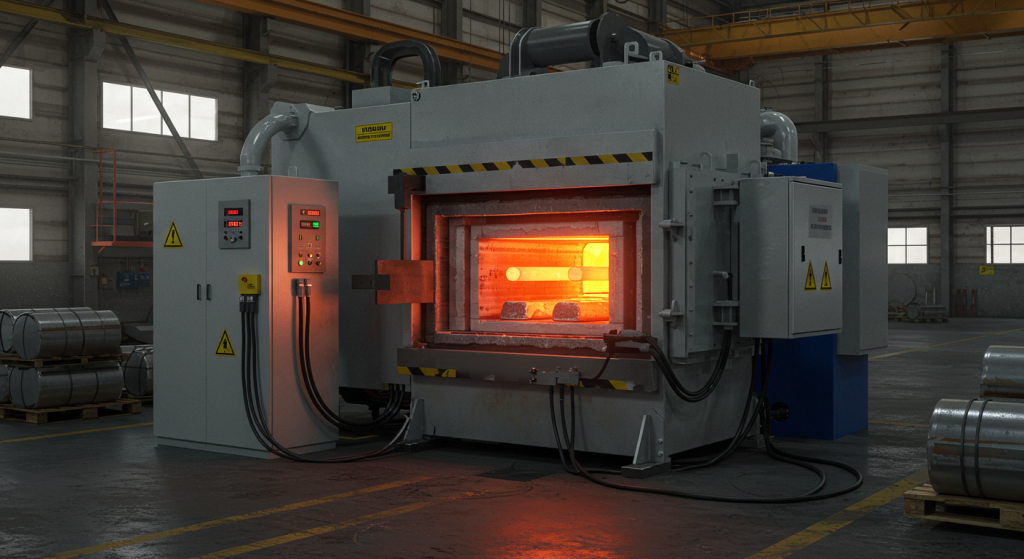

Industrial electric furnaces are specialized systems that use electrical energy to generate high temperatures for processing materials. They are essential for heat treatment processes like annealing, hardening, tempering, and melting, enabling industries to achieve desired material properties.

Key Functions

- Softens materials for improved machinability and forming.

- Enhances hardness and strength through controlled heating and quenching.

- Relieves internal stresses to improve material durability.

- Melts metals and alloys for casting or alloying.

Commonly Processed Materials

- Steel and stainless steel for structural and industrial components.

- Aluminum and titanium alloys for aerospace and automotive parts.

- Copper alloys for electrical applications.

- Ceramics and glass for specialized industrial uses.

These furnaces are critical for industries requiring precision and consistency in material performance under extreme conditions.

How Industrial Electric Furnaces Work

Industrial electric furnaces convert electrical energy into heat using various mechanisms, such as electric arcs, induction, or resistance heating. Each method offers unique advantages, making these furnaces versatile for different applications.

Heating Mechanisms

- Electric Arc Furnaces (EAF): Generate heat through an electric arc between electrodes and the material, reaching temperatures up to 1,800°C (3,300°F) for steelmaking and scrap recycling.

- Induction Furnaces: Use electromagnetic fields to induce eddy currents in the material, producing heat for melting and alloying with precise control.

- Resistance Furnaces: Heat materials via electrical resistance in heating elements or the material itself, ideal for laboratory and small-scale applications.

Core Components

- Heating Chamber: Insulated with refractory materials to withstand high temperatures.

- Temperature Control System: Employs microcomputer-based PID controls for precise temperature regulation.

- Atmosphere Management: Regulates gases to prevent oxidation or contamination during processing.

- Electrodes or Heating Elements: Conduct electricity to generate heat, often made of graphite, ceramics, or metals.

These components ensure uniform heating, energy efficiency, and material integrity, making electric furnaces indispensable in industrial settings.

Types of Industrial Electric Furnaces

Industrial electric furnaces come in various configurations, each tailored to specific processes and industries.

Electric Arc Furnaces

- Used for melting scrap steel and producing high-quality alloys.

- Common in mini-mills and foundries, with capacities from one to 400 tons.

- Ideal for steelmaking due to high temperatures and flexibility.

Induction Furnaces

- Employed for melting and holding metals like aluminum and zinc.

- Known for uniform alloy compositions and energy efficiency.

- Widely used in aerospace and automotive industries.

Resistance Furnaces

- Suited for annealing, tempering, and laboratory applications.

- Offer precise temperature control and clean operation.

- Common in ceramics, electronics, and small-scale heat treatment.

Vacuum Furnaces

- Process sensitive materials in oxygen-free environments.

- Used for titanium melting and vacuum arc remelting (VAR) in aerospace.

- Ensure high purity and minimal contamination.

Each type addresses specific industrial needs, from high-volume steel production to precision alloy processing.

Applications Across Industries

Industrial electric furnaces serve a wide range of sectors, enabling manufacturers to meet stringent quality and performance standards.

Key Applications

- Steelmaking: Produce stainless, electrical, and tool steels for automotive and chemical industries.

- Aerospace: Treat titanium and aluminum alloys for lightweight, durable components.

- Automotive: Harden and temper engine and transmission parts for enhanced reliability.

- Electronics: Anneal substrates to improve conductivity and performance.

- Ceramics and Glass: Process materials for industrial and optical applications.

Benefits for Manufacturers

- Enhanced material properties, improving product lifespan and performance.

- Precise process control, ensuring consistent quality and compliance.

- Reduced environmental impact compared to fuel-fired furnaces.

- Increased efficiency, lowering production costs and material waste.

These advantages make electric furnaces a cornerstone of modern industrial processes.

Jiangsu Yinuo’s Industrial Electric Furnace Solutions

Jiangsu Yinuo Thermal Energy Technology Co., Ltd., located in Jiangsu Province’s high-tech industrial zone, is a leading manufacturer of industrial electric furnaces. With a 70,000-square-meter facility, over 400 professionals, and 13 years of experience, the company delivers innovative solutions to global clients.

Why Jiangsu Yinuo Stands Out

- Innovation: Holds multiple patents, advancing electric furnace technology.

- Comprehensive Services: Provides design, installation, and after-sales support.

- Global Expertise: Over a decade of export experience, serving diverse markets.

- Quality Assurance: Engineers ensure compliance with ISO and CE standards.

- Customer-Centric: Offers tailored solutions for specific client needs.

Features of Jiangsu Yinuo’s Electric Furnaces

Jiangsu Yinuo’s furnaces are designed for precision, efficiency, and sustainability, addressing a wide range of industrial requirements.

Precision Temperature Control

- Operates from 200°C to 1300°C, supporting various heat treatment processes.

- Uses advanced PID control for uniform heating and tight tolerances.

- Customizable thermal cycles for specific material and process requirements.

Energy Efficiency

- Incorporates high-efficiency heating elements and insulation to minimize energy loss.

- Features regenerative systems to recycle heat, reducing electricity consumption.

- Aligns with sustainability goals through clean, emission-free operation.

Durable Construction

- Built with high-quality refractory materials and robust heating elements.

- Designed for minimal maintenance and long-term reliability.

- Modular configurations allow for easy upgrades and repairs.

Versatile Applications

- Supports annealing, hardening, tempering, and melting processes.

- Processes metals, alloys, ceramics, and glass with precision.

- Adapts to batch or continuous production for flexibility.

Customized Solutions

Jiangsu Yinuo tailors furnaces through a streamlined process:

- Consults with clients to define project specifications and objectives.

- Designs furnaces to meet material, process, and production goals.

- Manufactures with precision using state-of-the-art equipment.

- Provides on-site installation and commissioning for seamless integration.

- Offers ongoing maintenance and technical support to ensure performance.

This approach ensures furnaces meet the unique needs of clients, from small-scale laboratories to large-scale industrial plants.

Advantages of Electric Furnaces Over Traditional Furnaces

Industrial electric furnaces offer significant advantages over natural gas or coal-fired furnaces, making them a preferred choice for modern manufacturing.

Energy Efficiency

- Convert a higher percentage of energy into usable heat, reducing waste.

- Lower operating costs compared to fuel-fired systems with complex fuel delivery.

Environmental Sustainability

- Produce no direct emissions, unlike gas furnaces that emit greenhouse gases.

- Can be powered by renewable energy sources like solar or wind, further reducing carbon footprints.

Precise Control

- Offer superior temperature uniformity and control, critical for processes like annealing and tempering.

- Minimize temperature variations, ensuring consistent material quality.

Safety and Maintenance

- Eliminate risks of gas leaks or open flames, enhancing workplace safety.

- Require less maintenance, reducing downtime and repair costs.

Compact and Flexible Design

- Occupy less space and are easier to integrate into existing facilities.

- Support a wide range of applications, from melting to heat treatment.

These benefits make electric furnaces a sustainable and efficient solution for industrial heat treatment.

Energy Efficiency and Environmental Impact

Energy efficiency and sustainability are critical in today’s industrial landscape. Jiangsu Yinuo’s electric furnaces are designed to minimize environmental impact while maximizing performance.

Energy-Saving Features

- High-Efficiency Heating Elements: Optimize electricity use for maximum heat output.

- Advanced Insulation: Reduces heat loss, maintaining stable temperatures with less energy.

- Programmable Controls: Allow precise temperature management to avoid overuse.

Environmental Benefits

- Zero direct emissions, supporting compliance with strict environmental regulations.

- Reduced reliance on fossil fuels, lowering greenhouse gas emissions.

- Durable designs extend furnace lifespan, minimizing resource consumption.

Cost Savings

- Lower electricity bills through efficient energy use and regenerative systems.

- Reduced maintenance costs due to robust construction and fewer moving parts.

- Compliance with regulations avoids fines and supports long-term profitability.

These features align with global sustainability goals, making Jiangsu Yinuo’s furnaces a forward-thinking choice.

Quality Assurance at Jiangsu Yinuo

Quality is at the heart of Jiangsu Yinuo’s operations, ensuring every industrial electric furnace meets the highest standards of performance and reliability.

Rigorous Quality Control

- Engineers oversee design, material selection, and manufacturing processes.

- High-grade refractory materials and heating elements ensure durability.

- Comprehensive testing verifies performance before delivery.

Compliance and Documentation

- Complies with international standards like ISO 9001-2015 and CE certifications.

- Provides Certificates of Analysis and compliance documentation.

- Meets industry-specific requirements for aerospace, automotive, and electronics.

Customer Support Excellence

- Offers prompt issue resolution, with or without warranty, ensuring client satisfaction.

- Provides detailed manuals and operator training for seamless use.

- Ensures responsive communication via email, phone, or their official website.

This commitment to quality builds trust and fosters long-term client relationships.

The Future of Industrial Electric Furnaces

The industrial electric furnace sector is evolving, driven by technological advancements and sustainability demands. Jiangsu Yinuo is at the forefront of this transformation.

Emerging Trends

- Automation: IoT and PLCs enable real-time monitoring and process optimization.

- Smart Furnaces: Data analytics improve thermal profiles and predict maintenance needs.

- Sustainability: Increased use of renewable energy and electric furnaces to reduce emissions.

- Customization: Growing demand for furnaces tailored to niche applications, like superalloy production.

Jiangsu Yinuo’s Strategy

- Invests in R&D to develop next-generation electric furnace technologies.

- Expands global reach to serve emerging markets in Asia, Africa, and beyond.

- Collaborates with clients to create solutions for new materials and processes.

By embracing these trends, Jiangsu Yinuo ensures its furnaces remain industry leaders.

Choosing the Right Industrial Electric Furnace

Selecting the ideal furnace requires careful consideration to align with production needs and operational goals.

Key Considerations

- Material Compatibility: Ensure the furnace supports specific materials like steel or ceramics.

- Process Requirements: Choose furnaces for annealing, hardening, or melting as needed.

- Capacity and Scale: Opt for batch furnaces for flexibility or continuous for high volume.

- Atmosphere Needs: Select vacuum or gas systems for sensitive materials.

- Energy Efficiency: Prioritize high-efficiency elements and insulation for cost savings.

Partnering with Jiangsu Yinuo

- Consult with their expert team to define project requirements.

- Request a customized furnace design tailored to your specifications.

- Benefit from professional installation and ongoing technical support.

Jiangsu Yinuo’s expertise ensures a furnace that optimizes performance and efficiency.

Frequently Asked Questions

What is the primary function of an industrial electric furnace?

Industrial electric furnaces heat materials to enhance properties like strength, ductility, or conductivity for manufacturing applications.

What materials can Jiangsu Yinuo’s electric furnaces process?

Their furnaces process metals like steel and aluminum, alloys, ceramics, and glass, supporting diverse industrial needs.

How does Jiangsu Yinuo ensure furnace quality?

Engineers oversee production, using high-grade materials and rigorous testing, with compliance documentation for global standards.

Can Jiangsu Yinuo customize electric furnaces?

Yes, they design tailored furnaces, from consultation to installation, to meet specific client requirements and applications.

How energy-efficient are Jiangsu Yinuo’s electric furnaces?

Their furnaces feature high-efficiency elements, insulation, and regenerative systems to minimize energy use and costs.

How can I request a quote from Jiangsu Yinuo?

Visit their official website to submit a contact form, or contact via email or phone for a prompt response.

Conclusion: Elevate Your Operations with Jiangsu Yinuo

Industrial electric furnaces are transforming manufacturing with their precision, efficiency, and sustainability. Jiangsu Yinuo Thermal Energy Technology Co., Ltd. delivers innovative, reliable, and customized furnace solutions that empower global industries. With a focus on quality, environmental responsibility, and client satisfaction, they are the ideal partner for achieving manufacturing excellence.

Ready to enhance your production with a cutting-edge industrial electric furnace? Explore Jiangsu Yinuo’s offerings on their official website and connect with their team for a personalized quote. Power your industry with precision and sustainability today.