In the realm of industrial heating solutions, the pusher furnace has emerged as a highly efficient and versatile technology. Leading the charge in providing cutting-edge pusher furnace systems is JiangSu YiNuo Thermal Energy Technology Co., Ltd. With a commitment to innovation and quality, they have established themselves as a trusted manufacturer in the industry.

I. Understanding Pusher Furnace: What’s Pusher Furnace?

A. Definition and Operation

Definition: A pusher furnace is a type of continuous heat treatment furnace used in various industrial processes.

Operation: The pusher furnace consists of a continuous conveyor system that transports workpieces through heating zones, enabling efficient and controlled heat treatment.

B. Heating Techniques

Convection Heating: Utilizing hot air or gas, convection heating ensures uniform heat distribution within the furnace chamber. Radiant Heating: By employing electric or gas-fired radiant tubes, pusher furnaces enable direct heat transfer to the workpieces.

II. Key Features of YiNuo Pusher Furnaces

A. Customizability and Flexibility

YiNuo offers tailored pusher furnace solutions based on clients’ specific requirements, accommodating diverse applications and workpiece sizes. The modular design allows for easy integration into existing production lines, providing flexibility and scalability.

B. Energy Efficiency

Advanced insulation materials and efficient combustion systems minimize heat loss, increasing energy efficiency. Precise temperature control and automatic heat adjustment further optimize energy consumption.

C. Enhanced Productivity

The continuous conveyor system ensures a smooth and uninterrupted flow of workpieces, maximizing production output. Intelligent automation features, such as programmable logic controllers (PLCs), enable efficient process management and reduce human intervention.

III. Applications of Pusher Furnaces

A. Steel and Metal Industries

Pusher furnaces play a vital role in processes like annealing, normalizing, and tempering of steel and metal components. They ensure uniform heat treatment, improved mechanical properties, and increased product durability.

B. Automotive Sector

Pusher furnaces find application in heat treatment processes for automotive parts, such as gears, shafts, and engine components. These furnaces facilitate the development of high-quality and durable automotive components, meeting industry standards and regulations.

C. Glass Manufacturing

Pusher furnaces are utilized in glass manufacturing processes, including annealing and tempering, to improve product strength and durability. Precise temperature control and uniform heating ensure consistent glass quality and reduce production defects.

IV. The YiNuo Advantage

A. Expertise and Experience

JiangSu YiNuo Thermal Energy Technology Co., Ltd. boasts extensive experience in industrial heating solutions, including pusher furnaces. Their team of engineers and technicians possesses in-depth knowledge and expertise to provide optimal furnace designs and reliable after-sales support.

B. Cutting-Edge Technology

YiNuo integrates the latest technologies, such as advanced control systems and energy-saving components, into their pusher furnace solutions. Continuous research and development efforts ensure that their offerings remain at the forefront of industrial heating technology.

Ⅴ. Pusher Furnace: Continuous Steel Rolling Heating Furnaces

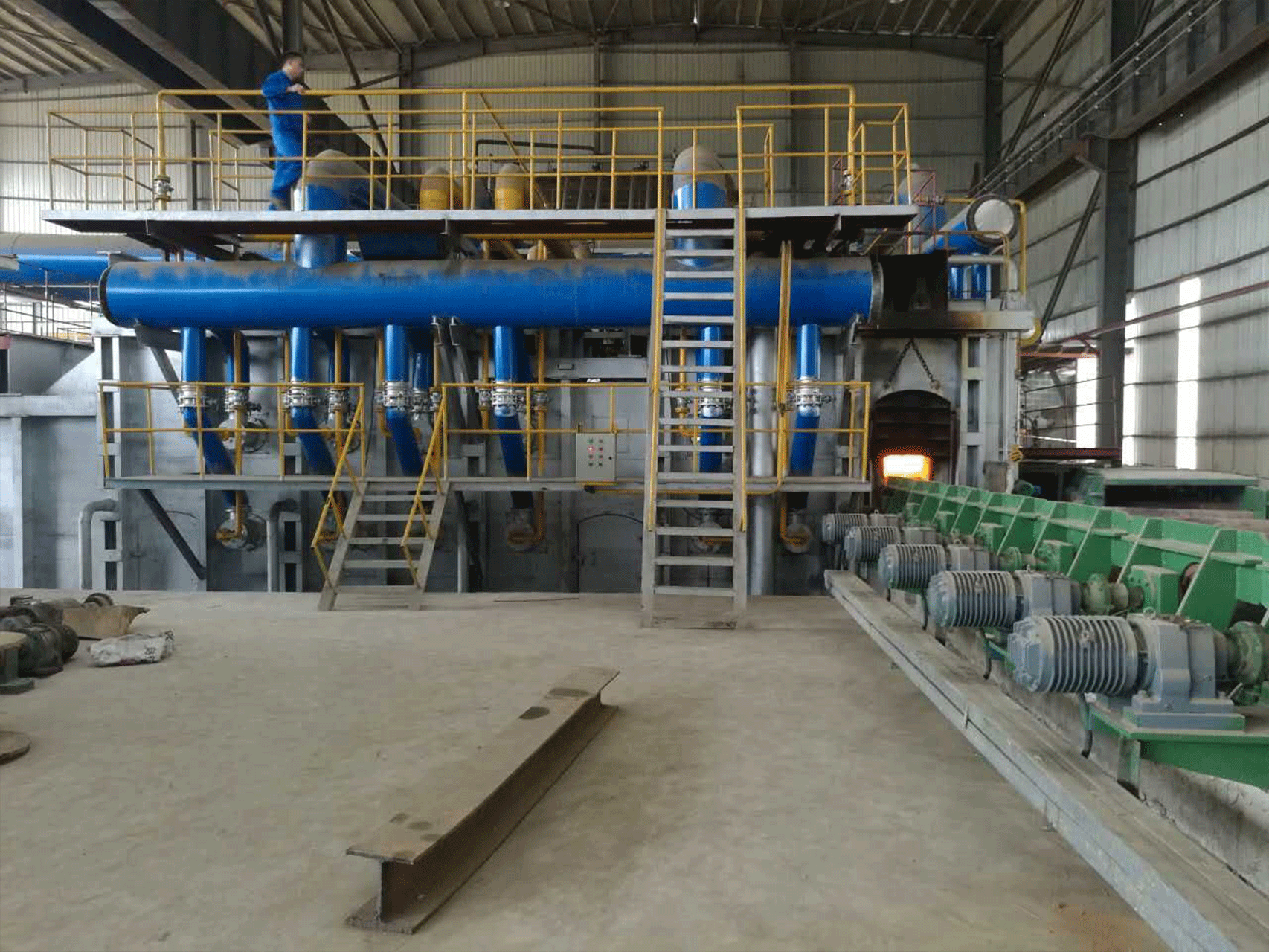

Continuous steel rolling heating furnaces are indispensable industrial furnaces in the steel manufacturing process. They play a vital role in heating steel billets or slabs to the precise temperature required for rolling them into finished products. These furnaces, operated by companies like JiangSu YiNuo Thermal Energy Technology Co., Ltd., are designed to work continuously, employing advanced technologies to ensure efficient and consistent heating.

A. Working Principle of Continuous Steel Rolling Heating Furnaces

Continuous steel rolling heating furnaces operate on the principle of heating steel billets or slabs to the optimal temperature before the rolling process. These furnaces incorporate a conveyor system that feeds steel into one end and transports it through the furnace to the other end. The furnaces are divided into multiple heating zones, each equipped with its own heating source and temperature control system.

As the steel moves along the conveyor, it passes through each heating zone, where it is subjected to carefully controlled temperature profiles. These profiles ensure that the steel reaches the desired temperature for rolling. The heating sources employed in continuous steel rolling heating furnaces can vary, including natural gas or electric heating elements. The heat is directed onto the steel using a combination of radiant heat and convection, facilitating efficient and uniform heating.

B. Temperature Control and Quality Assurance

Temperature control is a critical aspect of continuous steel rolling heating furnaces. To ensure optimal rolling conditions, the furnaces are equipped with temperature control systems that consist of sensors and control algorithms. These systems monitor the steel’s temperature as it progresses through the stove, adjusting the temperature of each heating zone accordingly to maintain the desired temperature profile.

The precise control of temperature in continuous furnaces is essential to achieve consistent and high-quality results. It ensures that the steel is heated uniformly, eliminating any variations that could lead to defects in the finished products. By maintaining a consistent temperature profile throughout the billets or slabs, the furnaces produce steel with the required properties, such as strength and durability.

C. Efficiency and Productivity Advantages

Continuous steel rolling heating furnaces offer several advantages in terms of efficiency and productivity. Their continuous operation allows for the rapid processing of large volumes of steel, reducing production time and costs. By eliminating the need for batch processing, these furnaces enable a seamless flow of steel through the manufacturing process.

Moreover, precise temperature control in continuous furnaces contributes to energy efficiency. The ability to maintain consistent temperatures reduces energy wastage and ensures that the steel is heated to the required level without overheating. This energy-efficient approach helps companies reduce their carbon footprint and minimize operating costs.

Manufacturers like JiangSu YiNuo Thermal Energy Technology Co., Ltd. continue to innovate in this field, developing advanced furnace technologies that enhance efficiency and productivity in the steel manufacturing process. By incorporating state-of-the-art heating sources and temperature control systems, these manufacturers enable their clients to achieve optimal results while meeting the demands of a competitive market.

Conclusion

JiangSu YiNuo Thermal Energy Technology Co., Ltd. stands as a leading manufacturer of pusher furnaces, providing efficient and customizable solutions for various industries. With their commitment to innovation, energy efficiency, and customer satisfaction, YiNuo sets a high standard in the market. As the demand for reliable and high-performance heating solutions continues to rise, YiNuo’s pusher furnaces are well-equipped to meet the evolving needs of industries worldwide.