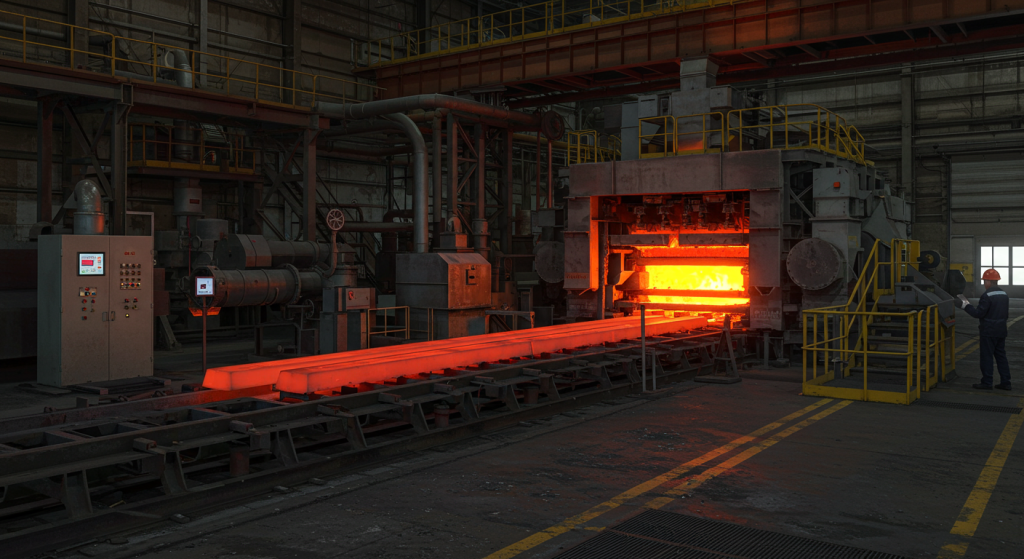

Regenerative burner reheating furnaces are transforming steel processing by delivering exceptional energy efficiency and sustainability. These furnaces preheat steel billets, blooms, or slabs for hot rolling, forging, or extrusion, using advanced regenerative burner technology to recover waste heat and reduce fuel consumption. At Jiangsu Yinuo Thermal Energy Technology Co., Ltd., based in Xuzhou, China, we lead the industry with innovative regenerative burner reheating furnace solutions. This guide explores the technology, benefits, and applications of these furnaces, showcasing why our expertise at Jiangsu Yinuo is trusted globally.

The Importance of Regenerative Burner Reheating Furnaces

Regenerative burner reheating furnaces are designed to heat steel continuously, ensuring uniform temperatures for downstream processes like rolling or forging. We integrate regenerative burners into our furnaces to capture and reuse exhaust heat, achieving up to 50% fuel savings compared to traditional systems. This efficiency is critical for steel manufacturing, where energy costs are significant, making our furnaces a cornerstone of cost-effective and environmentally responsible production.

Purpose of Reheating with Regenerative Burners

Our regenerative burner reheating furnaces heat steel to temperatures between 1100°C and 1250°C, enhancing ductility for hot rolling or forging. By recovering waste heat, we reduce fuel use, lowering operational costs and emissions. Uniform heating eliminates thermal gradients, preventing defects like cracks and ensuring consistent microstructure. This process optimizes steel properties, producing high-quality components for construction, automotive, and infrastructure applications, meeting stringent industry standards.

Steel Types Processed

We design our furnaces to process various steel grades, addressing diverse industrial needs. Carbon steel billets, common in construction, are preheated for rolling into structural shapes or rebar. Alloy steels, enhanced with elements like chromium or vanadium, are processed for high-strength components in automotive and aerospace sectors. Stainless steel, valued for corrosion resistance, is heated for specialized applications. Our furnaces’ versatility ensures compatibility with multiple steel types, supporting a broad range of production requirements.

How Regenerative Burner Reheating Furnaces Operate

Regenerative burner reheating furnaces function as continuous heating systems, moving steel through thermal zones using pusher or walking beam mechanisms. We equip our furnaces with regenerative burner systems that cycle between firing and exhaust modes, recovering heat to preheat combustion air, ensuring efficiency and precision in demanding industrial environments.

Core Components

Our furnaces feature a heating chamber lined with high-grade refractory materials, capable of withstanding temperatures up to 1300°C while minimizing heat loss. We include advanced temperature control systems with PID controllers for precise thermal regulation. Regenerative burners, operating in pairs, incorporate ceramic regenerators for heat storage and transfer. Switching valves alternate between combustion and exhaust cycles, while PLC-based controls manage cycle timing and airflow. Atmosphere control systems regulate oxygen levels, preventing scaling or oxidation during heating.

Operational Mechanism

In our regenerative burner reheating furnaces, steel billets or slabs are loaded onto a hearth or skids. The pusher or walking beam mechanism advances the steel through preheating, heating, and soaking zones. In the burner system, one burner fires fuel and preheated air, while its pair exhausts hot flue gases through a regenerator, storing heat in ceramic media. After 20–60 seconds, the valves switch, reversing roles: the exhaust burner fires, using stored heat to preheat air to 1000–1200°C. This cycle ensures continuous heat recovery, minimizing fuel use and maintaining stable furnace temperatures.

Applications in Steel Processing

Regenerative burner reheating furnaces are vital across steel-related industries, enabling the production of high-quality components with consistent properties. Our furnaces support continuous operation, delivering the precision and efficiency needed for large-scale manufacturing.

Hot Rolling Mills

Our furnaces preheat steel billets, blooms, or slabs for hot rolling into sheets, plates, or rebar. Regenerative burners reduce fuel consumption while maintaining temperatures of 1100–1250°C, ensuring uniform heating for consistent steel properties. We support the production of steel for construction, shipbuilding, and infrastructure, where reliability is critical. Our high-throughput furnaces meet the demands of large-scale rolling mills, enhancing efficiency and quality.

Rebar Production

In rebar production, we use our furnaces to heat carbon or low-alloy steel billets for rolling into reinforcing bars for concrete structures. Uniform heating ensures rebar achieves the tensile strength and ductility needed for buildings and bridges. Our regenerative burners minimize energy costs, making our furnaces ideal for high-volume rebar manufacturing, supporting global infrastructure development with sustainable solutions.

Automotive and Machinery Components

Our furnaces preheat alloy steels for rolling or forging into automotive and machinery components like gears, axles, and chassis parts. The burners’ efficiency ensures precise temperature control, minimizing scaling and improving material quality. We enable manufacturers to produce durable, high-strength parts that meet strict safety standards, supporting the automotive industry’s demand for reliable, cost-effective production.

Specialty Steel Applications

For specialty applications, our furnaces heat stainless or high-alloy steels for rolling into corrosion-resistant or high-performance components used in chemical plants or aerospace. Our atmosphere control prevents oxidation, ensuring high-quality steel. The energy savings from our regenerative burners make these furnaces ideal for niche markets requiring premium materials, delivering both performance and sustainability.

Jiangsu Yinuo’s Reheating Furnace Expertise

At Jiangsu Yinuo Thermal Energy Technology Co., Ltd., we operate a 70,000-square-meter facility in Jiangsu Province’s high-tech industrial zone, staffed by over 400 professionals with 13 years of global experience. We specialize in manufacturing regenerative burner reheating furnaces that set industry standards for efficiency, performance, and reliability.

Why Jiangsu Yinuo Leads the Industry

We hold multiple patents, reflecting our innovation in regenerative burner and furnace technology. Our comprehensive services include custom design, installation, and after-sales support, ensuring seamless project execution. With extensive export experience, we meet diverse industrial standards, serving clients worldwide. Our rigorous quality control, overseen by expert engineers, ensures compliance with ISO 9001 and CE certifications. We prioritize customer needs, delivering tailored solutions that align with production goals, making us a trusted partner in steel processing.

Features of Jiangsu Yinuo’s Reheating Furnaces

Our regenerative burner reheating furnaces are engineered for precision and durability. We equip them with advanced temperature control systems, maintaining temperatures from 800°C to 1300°C for uniform heating. Our regenerative burners reduce fuel use by up to 50%, with high-quality insulation minimizing heat loss. Built with premium refractory materials, our furnaces ensure longevity and low maintenance. We support continuous processing of steel billets or slabs, with flexible configurations for various sizes. Our atmosphere control systems prevent scaling, delivering high-quality steel ready for rolling or forging.

Customization for Steel Processing

We excel at delivering bespoke reheating furnace solutions. Our process begins with client consultations to understand material and production requirements, followed by designing furnaces tailored to specific needs. We manufacture in our advanced facility, using cutting-edge equipment for precision. Our team handles on-site installation and commissioning, ensuring seamless integration, and we provide ongoing support to maximize performance. This tailored approach ensures our furnaces align with client operations, from large-scale rolling mills to specialized steel plants.

The Reheating Process in Our Furnaces

Reheating in our regenerative burner furnaces is a multi-stage process that ensures steel is optimally conditioned for hot rolling or forging. We control each stage to achieve uniform temperatures and material properties, critical for high-quality steel production.

Preheating Stage

In the preheating stage, we gradually warm steel billets or slabs from ambient temperatures to 600–800°C to avoid thermal shock. This reduces internal stresses and prepares the material for higher temperatures. Our furnaces ensure uniform heat distribution, preventing uneven expansion that could cause defects. We use controlled burner settings and advanced insulation to maintain consistent preheating across large loads.

Heating Stage

Our heating stage raises steel to its target temperature, typically 1100–1250°C, ensuring ductility for rolling or forging. We prevent overheating, which could alter microstructure or cause scaling, using precise temperature control via PID controllers. Our regenerative burners optimize energy use, delivering high heat output with minimal fuel. This stage ensures uniform heating, critical for consistent mechanical properties and surface quality in the final product.

Soaking Stage

In the soaking stage, we hold steel at the target temperature to ensure uniform heat penetration, particularly for thick slabs or blooms. This eliminates temperature gradients, ensuring the core and surface are equally malleable. Our atmosphere control systems, using inert gases or controlled combustion, prevent oxidation or decarburization. The pusher or walking beam mechanism maintains steady movement, ensuring consistent soaking times for optimal preparation.

Energy Efficiency and Sustainability

Energy efficiency is a priority in steel processing, driven by cost and environmental concerns. We design our regenerative burner reheating furnaces at Jiangsu Yinuo to minimize energy use while maintaining top performance.

Energy-Saving Technologies

Our regenerative burners recover 85–90% of waste heat, preheating combustion air to 1000–1200°C, reducing fuel consumption by 30–50%. We use high-quality insulation to minimize heat loss, maintaining stable temperatures with less energy. Our advanced control systems optimize burner cycles, avoiding waste during idle periods. For clients seeking cleaner options, we offer electric-enhanced systems, further enhancing sustainability.

Environmental Benefits

Our furnaces produce fewer CO2 emissions due to reduced fuel use, aligning with global sustainability goals. We minimize NOx formation through optimized combustion, complying with environmental regulations. Our controlled atmospheres reduce harmful byproducts like oxides, lowering environmental impact. Our durable furnace designs extend service life, conserving resources. These features help clients achieve greener steel production without sacrificing performance.

Cost Savings

Our energy-efficient furnaces lower fuel bills, delivering significant savings. We ensure precise heating to reduce material waste and rework, boosting efficiency. Our reliable furnaces minimize downtime and maintenance costs, supporting consistent production. By combining sustainability with economic benefits, we provide cost-effective solutions for steel manufacturers, enhancing profitability.

Quality Assurance and Support

At Jiangsu Yinuo, we ensure every regenerative burner reheating furnace meets the highest standards of performance and reliability through rigorous quality processes.

Stringent Quality Control

Our engineers oversee every production stage, from design to testing, ensuring precision and durability. We select premium refractory materials and ceramic regenerators to withstand extreme conditions. Each furnace undergoes rigorous testing to verify temperature accuracy, burner efficiency, and mechanism reliability, guaranteeing consistent performance in steel processing.

Compliance and Documentation

We ensure our furnaces comply with international standards, including ISO 9001 and CE certifications, ensuring global acceptability. We provide comprehensive documentation, such as Certificates of Analysis and compliance reports, to meet industry requirements. This is critical for steel manufacturing, where regulatory compliance and traceability are essential.

Exceptional Customer Support

We offer prompt issue resolution, ensuring minimal disruption to client operations. Our detailed manuals and operator training facilitate seamless furnace use. Clients can access support via email, phone, or our Jiangsu Yinuo website, with our responsive team ready to assist. Our dedication to service strengthens our reputation as a trusted partner.

The Future of Regenerative Burner Reheating Furnaces

The reheating furnace industry is advancing, driven by technology and sustainability demands. We are shaping the future at Jiangsu Yinuo with innovative solutions.

Emerging Trends

We see automation enhancing furnaces with AI-driven controls and IoT for real-time optimization. Our smart furnaces use predictive analytics to refine heating and reduce downtime. We focus on sustainability, integrating renewable energy and ultra-low NOx burners. We also address demands for furnaces supporting advanced steel grades, ensuring adaptability for future applications.

Jiangsu Yinuo’s Vision

We invest in R&D to pioneer new furnace technologies. Our expansion into emerging markets strengthens our global presence. By collaborating with clients, we develop solutions for cutting-edge applications, ensuring our furnaces remain industry leaders. Our forward-thinking approach positions us as a reliable partner for future challenges in steel processing.

Choosing the Right Reheating Furnace

Selecting the ideal regenerative burner reheating furnace requires careful evaluation to align with production needs.

Key Factors to Consider

We ensure our furnaces support specific steel grades, such as carbon or alloy steels, for compatibility. The intended process—rolling, forging, or extrusion—determines furnace capacity and temperature range. We offer high-throughput furnaces for large-scale production. Our atmosphere control prevents scaling, critical for quality output. We prioritize energy efficiency to reduce costs and emissions.

Partnering with Jiangsu Yinuo

Our team at Jiangsu Yinuo provides expert guidance, collaborating with clients to understand their needs. We design custom furnaces tailored to specific goals. Our installation and support ensure optimal performance, delivering value. Clients can connect through our website for tailored solutions.

Frequently Asked Questions

What is the purpose of a regenerative burner reheating furnace?

Our furnaces preheat steel for hot rolling or forging, using regenerative burners to reduce fuel use and emissions.

What steel types can Jiangsu Yinuo’s furnaces process?

We process carbon steel, alloy steel, and stainless steel, supporting construction and automotive applications.

How does Jiangsu Yinuo ensure furnace quality?

Our engineers oversee production with rigorous testing and premium materials, providing documentation to meet ISO and CE standards.

Are Jiangsu Yinuo’s furnaces customizable?

Yes, we design tailored furnaces, offering support from design to installation for optimal performance.

How energy-efficient are Jiangsu Yinuo’s furnaces?

Our furnaces reduce fuel use by up to 50% through regenerative burners, lowering costs and emissions.

How can I request a quote from Jiangsu Yinuo?

Clients can submit a contact form or reach out via email or phone through our website for a prompt response.

Conclusion: Transform Your Steel Processing with Jiangsu Yinuo

Regenerative burner reheating furnaces are redefining steel processing, offering energy efficiency and sustainability for hot rolling and forging. At Jiangsu Yinuo Thermal Energy Technology Co., Ltd., we deliver innovative, customized solutions that empower manufacturers worldwide. With our focus on precision, sustainability, and client satisfaction, we are the ideal partner for achieving steel processing excellence. Explore our offerings and connect through our website for a personalized quote to elevate your production today.