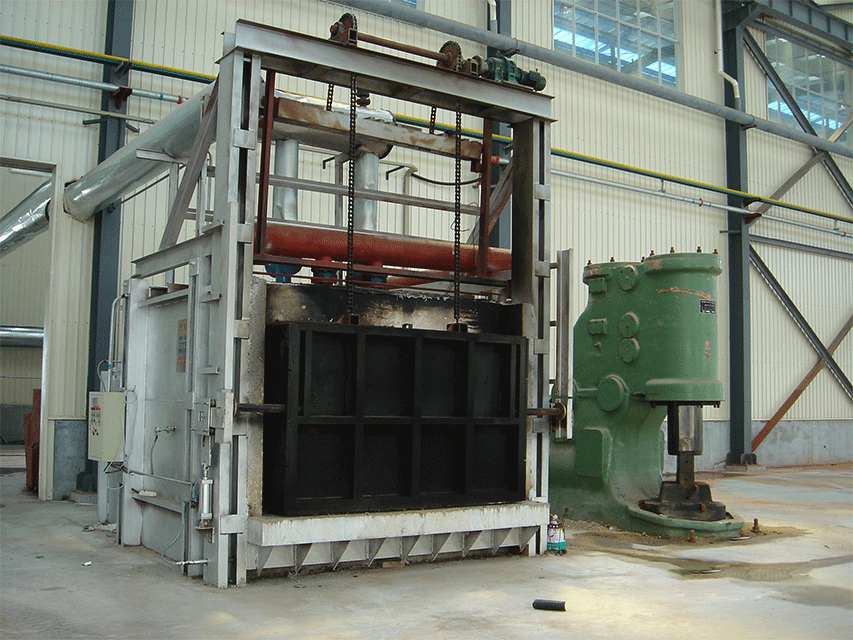

A Regenerative Forging Heating Furnace is a specialized industrial furnace used in the metal forging industry to heat billets, ingots, or other raw materials before forging. Known for its high thermal efficiency and energy-saving capabilities, this type of furnace is widely applied in the production of forged metal components.

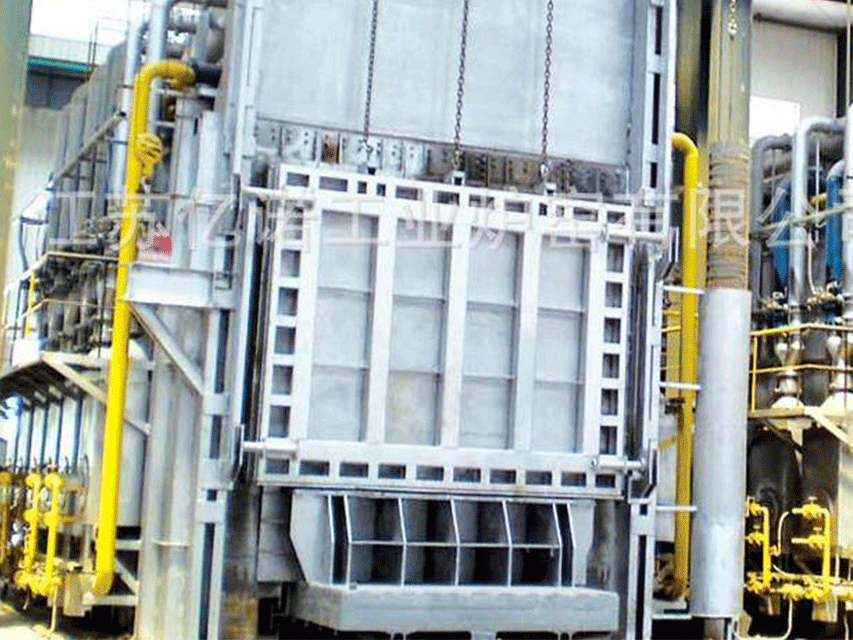

The furnace operates using regenerative burners that alternate between heating and heat recovery modes. Positioned at opposite ends of the furnace, these burners are connected to regenerators—refractory-lined chambers filled with ceramic media that store heat from the exhaust gases. This system enables the reuse of thermal energy, significantly reducing fuel consumption and emissions.

Additionally, the furnace typically includes a conveyor or pusher system to move materials through the heating zones, ensuring uniform heat distribution and minimizing the occurrence of temperature inconsistencies such as hot spots or cold spots.

Overall, the Regenerative Forging Heating Furnace offers an efficient, cost-effective, and environmentally friendly solution for preheating metal materials in forging applications.

Working Principle of Regenerative Forging Heating Furnace

The Regenerative Forging Heating Furnace operates on a cyclical process of heat storage and transfer, using regenerative burners and ceramic regenerators. The core steps of its working principle include:

1. Combustion and Heating

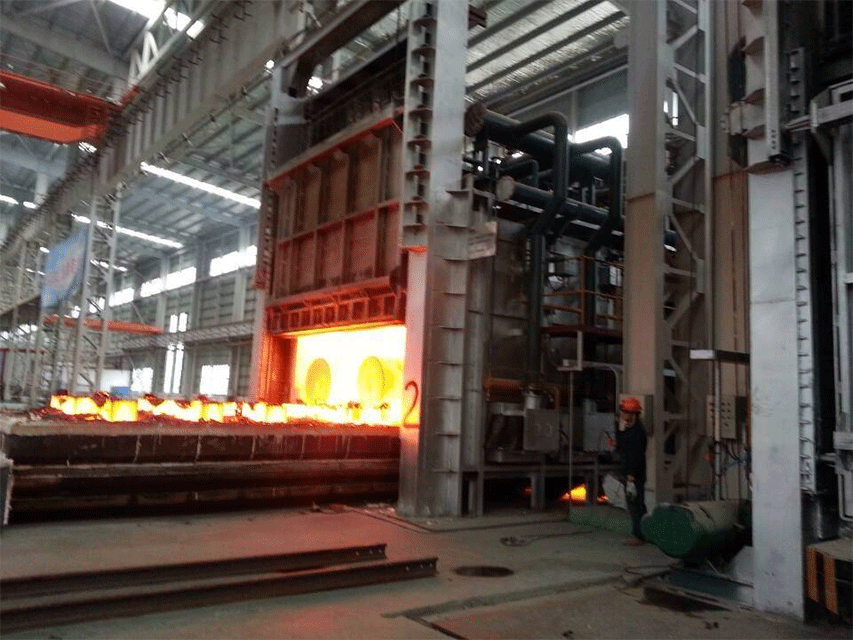

The furnace is equipped with two or more burners located at opposite ends. Fueled by natural gas or another combustible source, the burners heat the metal materials as they pass through the furnace.

2. Exhaust Heat Capture

As the burners operate, the resulting hot exhaust gases are directed through the regenerators—chambers lined with refractory materials and filled with ceramic elements. These ceramics absorb and store the thermal energy from the exhaust gases.

3. Heat Storage and Reuse

After the regenerators are heated, the system switches cycles. The burners are briefly shut off, and the stored heat in the ceramics is used to preheat incoming combustion air. This dramatically improves fuel efficiency and reduces energy waste.

4. Material Handling

A conveyor or pusher-type transport system moves raw materials through the furnace, ensuring consistent exposure to heat. This movement allows for uniform heating, which is critical for quality forging results.

5. Alternating Regeneration

The direction of airflow is periodically reversed. While one regenerator preheats incoming air, the other absorbs heat from the outgoing exhaust. This alternating cycle allows continuous regeneration of energy with minimal loss.

The characteristics

The Regenerative Forging Furnace is known for several key characteristics, including:

- High efficiency: The Regenerative Forging Furnace is highly efficient due to its use of regenerative burners and ceramic regenerators, which allow for efficient heat storage and transfer. This results in reduced fuel consumption and lower operating costs.

- Even heating: The furnace features a conveyor system that moves the raw material through the furnace for even heating, reducing the risk of hot spots or cold spots.

- Precise temperature control: The Regenerative Forging Furnace is equipped with advanced temperature control systems that allow for precise control over the heating process, ensuring high-quality finished products.

- Versatility: The furnace can be used to heat a wide range of metal raw materials, including billets, ingots, and other shapes.

- Reduced emissions: The use of regenerative burners and ceramic regenerators in the furnace results in reduced emissions compared to traditional furnace designs.