Regenerative gas-fired forging furnaces are critical tools in modern metalworking processes. These furnaces use natural gas or other fuel sources to heat metals to extremely high temperatures, making them malleable and easier to work with. One of the leading manufacturers of regenerative gas-fired forging furnaces is Jiangsu YiNuo Thermal Energy Technology Co., Ltd.

What’s Regenerative Gas Fired Forging Furnace?

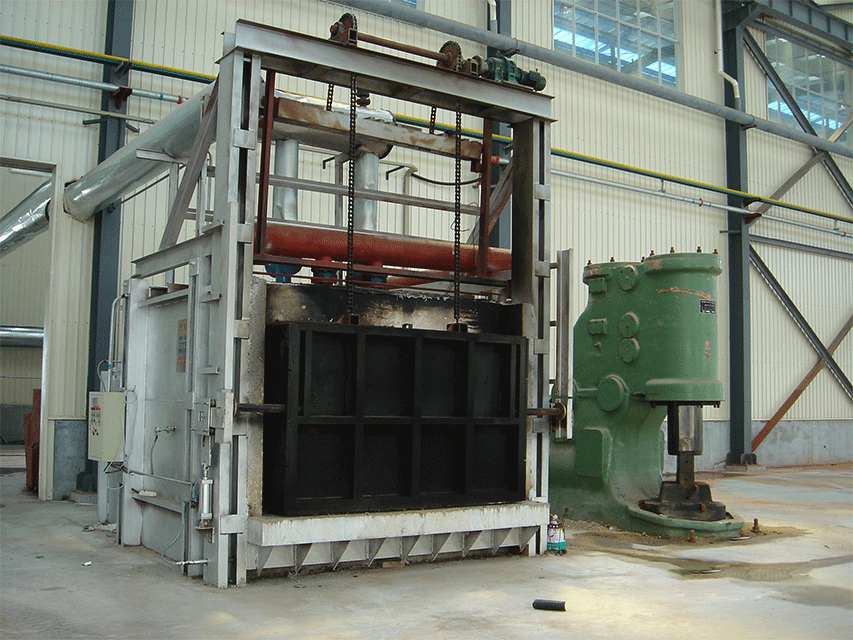

A regenerative gas-fired forging furnace burns natural gas or other fuels in a combustion chamber. The heat generated from this process is then directed towards the furnace’s refractory-lined chamber, where the metal being worked is placed. This high temperature melts and softens the metal, making it easier to forge and shape.

One of the key features of regenerative gas-fired forging furnaces is their use of regenerative burners. These burners use a heat exchanger to preheat the combustion air, which increases the efficiency of the furnace and reduces its environmental impact. In addition, regenerative burners also allow the furnace to operate at higher temperatures while reducing fuel consumption.

One prominent manufacturer of regenerative gas-fired forging furnaces is Jiangsu YiNuo Thermal Energy Technology Co., Ltd. They offer a range of furnaces suitable for various industrial applications, including forging, heat treating, and casting. Their furnaces are designed to meet the specific needs of their clients, with customizable options available for temperature range, capacity, and control systems. YiNuo’s furnaces are also equipped with advanced features, such as automatic temperature control and digital displays, which ensure optimal performance and efficiency.

How to Choose the Right Regenerative Gas Fired Forging Furnace?

When choosing a regenerative gas-fired forging furnace, there are several factors to consider. First and foremost, the furnace should be able to achieve the required temperature range for the metal being worked. Additionally, the furnace should be easy to operate and maintain, with controls and monitoring systems that allow for precise temperature regulation.

Safety is also important, as high temperatures and combustible fuel sources can pose significant risks. A good regenerative gas-fired forging furnace should have safety features such as automatic shut-off systems in case of malfunctions, as well as proper ventilation and exhaust systems to prevent the buildup of toxic fumes.

JiangSu YiNuo Thermal Energy Technology Co., Ltd. is a leading regenerative gas-fired forging furnaces manufacturer. Their furnaces are designed to be highly efficient, with advanced regenerative burner technology that reduces fuel consumption and environmental impact. They also prioritize safety, with features such as automatic shut-off systems and proper ventilation.

Regenerative Gas Fired Forging Furnace: Eco-Friendly Solution for Your Forging Needs

Regenerative gas-fired forging furnaces have become increasingly popular in recent years due to their eco-friendly features and high energy efficiency. These furnaces work on a regenerative principle, which allows for the continuous regeneration of heat, reducing the need for excessive fuel consumption.

The regenerative gas-fired forging furnace from JiangSu YiNuo Thermal Energy Technology Co., Ltd. is designed with a ceramic heat exchanger that allows for the efficient transfer of heat from the hot gases to the incoming air and fuel mixture. This preheating of the air and fuel mixture allows for more efficient combustion and significantly reduces fuel consumption.

The heat exchanger in these furnaces is designed with two chambers, one for heating and one for cooling. The hot gases flow through the heating chamber, and the cooled gases flow through the cooling chamber, which is filled with a material such as ceramic bricks or honeycomb structures that can absorb and store heat. The furnace’s combustion control system monitors the temperature and oxygen levels in the combustion chamber and adjusts the fuel and air mixture to maintain optimal combustion efficiency, ensuring the furnace operates at peak efficiency at all times.

Stay Ahead of the Competition with Regenerative Gas Fired Forging Furnace

In today’s highly competitive market, businesses are always looking for ways to stay ahead of their competition. One solution that has gained popularity in recent years is the use of regenerative gas-fired forging furnaces. These furnaces offer several advantages over traditional furnaces and can significantly improve the efficiency and effectiveness of forging operations.

JiangSu YiNuo Thermal Energy Technology Co., Ltd. is a leading regenerative gas-fired forging furnaces manufacturer. Their furnaces are designed to meet the unique needs of the forging industry and provide a range of benefits to businesses that use them.

The high energy efficiency of regenerative gas-fired forging furnaces makes them a more sustainable option for businesses. Regenerative furnaces can recover a significant amount of heat generated during the combustion process, reducing energy consumption and fuel costs. This translates into significant cost savings for businesses and makes regenerative furnaces a more sustainable option compared to traditional furnaces.

Reduce Costs and Increase Efficiency with Regenerative Gas Fired Forging Furnace

Regenerative gas fired forging furnaces are a critical component of the forging industry, and they are widely used to heat and shape metals. As with any industrial process, reducing costs and increasing efficiency is a top priority. The good news is that with the help of regenerative gas fired forging furnaces, companies can achieve both of these goals.

JiangSu YiNuo Thermal Energy Technology Co., Ltd is a leading manufacturer of regenerative gas fired forging furnaces that help businesses reduce costs and increase efficiency. Here’s how:

1. Reduced Natural Gas Consumption

Natural gas is the primary fuel source for most forging furnaces. JiangSu YiNuo’s furnaces are designed to optimize the use of natural gas, using just 350Nm3/h for a heat value of 8900Kcal/Nm3. By reducing the amount of natural gas used, companies can save money on energy costs and reduce their carbon footprint.

2. Water Conservation

JiangSu YiNuo’s furnaces also help companies conserve water. The cycle water consumption for their furnaces is just 12m3/h, while soft water consumption is 4m3/h. By using less water, companies can save money on water costs and reduce their environmental impact.

3. Low Electricity Consumption

In addition to reducing natural gas and water consumption, JiangSu YiNuo’s furnaces have a low electricity consumption rate of just 5KWh/t. This means that companies can save money on their electricity bills while maintaining a high level of productivity.

Conclusion

Regenerative gas-fired forging furnaces are an important tool in modern metalworking processes. When choosing a furnace, it is important to consider factors such as temperature range, ease of operation and maintenance, and safety features. JiangSu YiNuo Thermal Energy Technology Co., Ltd. is a trusted manufacturer of regenerative gas-fired forging furnaces, with a reputation for quality, efficiency, and safety.