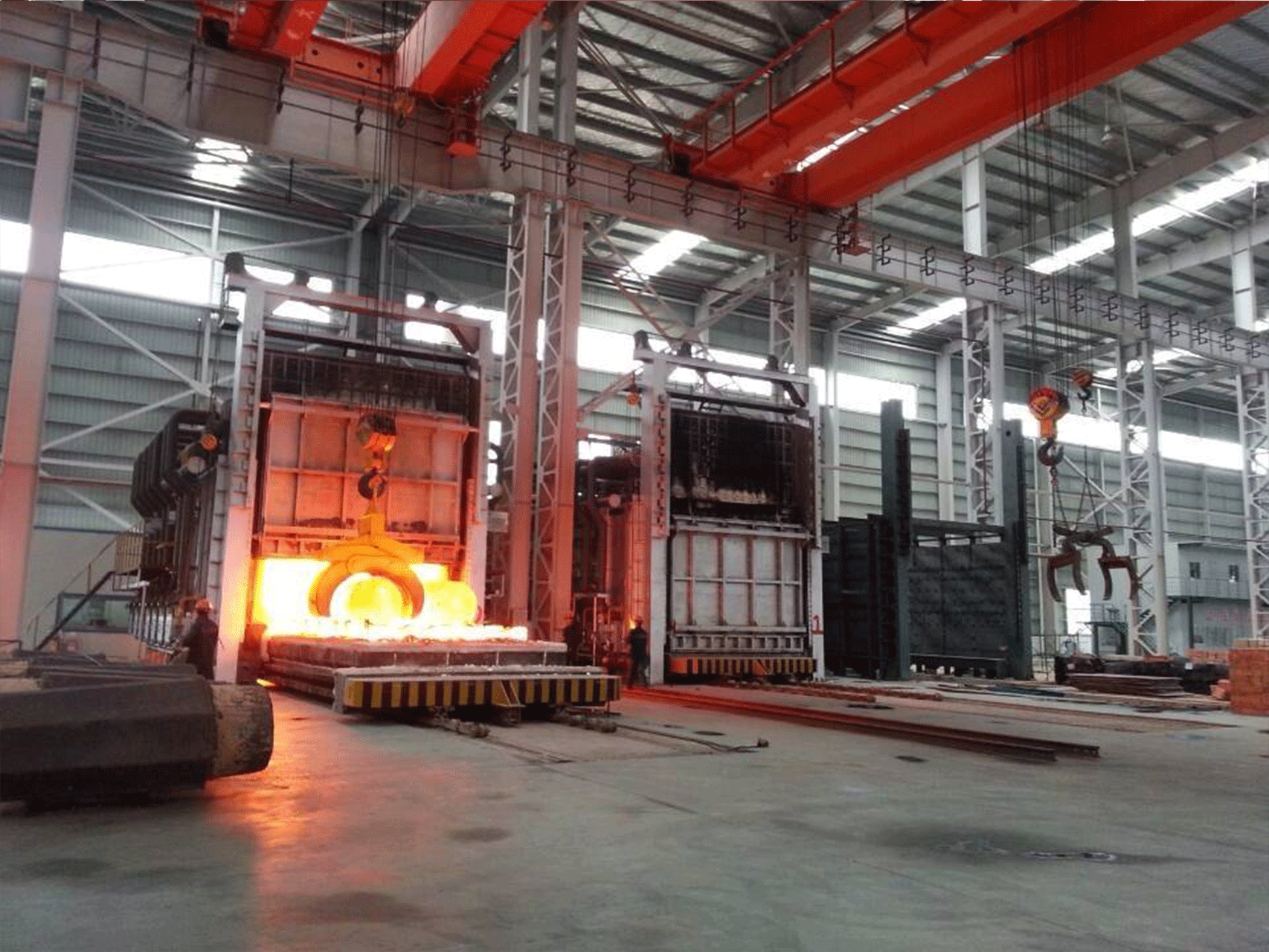

A Regenerative Trolley Type Heating Furnace is a specialized industrial furnace used for heating and treating metal products. It utilizes a regenerative heating process, where heat energy is captured and reused within the system, significantly improving energy efficiency and reducing operational costs.

This furnace typically features a tunnel- or chamber-shaped structure, with a series of heat-resistant trolleys—made from materials like steel or ceramic—that transport metal products through various heating zones. It’s widely used in industries such as steel production, forging, and metal heat treatment due to its consistent performance and energy-saving capabilities.

Working Principle of Regenerative Trolley Type Heating Furnace

The Regenerative Trolley Type Heating Furnace operates based on regenerative heating technology. This involves a system of heat exchangers—known as regenerators—that store thermal energy from hot exhaust gases during the combustion cycle. Here’s how it works:

-

Heat Recovery: During operation, the hot exhaust gases flow through one regenerator, which absorbs and stores the heat.

-

Heat Reuse: In the next cycle, the stored heat is released to preheat incoming combustion air, significantly reducing fuel consumption.

-

Continuous Operation: Trolleys continuously move through the furnace, passing through different temperature-controlled zones for optimal and uniform heating.

-

Precise Control: Parameters like temperature, atmosphere, and flow rate are precisely managed to ensure consistent quality in the treated metal products.

This cycle of heat recovery and reuse leads to a more efficient, cost-effective, and environmentally friendly heating process.

Key Characteristics of Regenerative Trolley Type Heating Furnaces

-

Regenerative Heating Technology: Maximizes energy usage by capturing and reusing thermal energy, making the system highly efficient.

-

Continuous Operation: Designed for uninterrupted processing, with trolleys moving through the furnace for steady workflow and uniform heating.

-

Energy Efficiency: Significantly lowers fuel consumption compared to conventional furnaces, leading to long-term cost savings.

-

Reduced Emissions: Lower energy use results in fewer emissions, supporting environmental compliance and sustainability goals.

-

Versatile Applications: Ideal for steel production, forging operations, and various heat treatment processes.

-

Multi-Zone Heating Control: Features multiple independently controlled heating zones, allowing precise thermal management for different stages of the heating process.

-

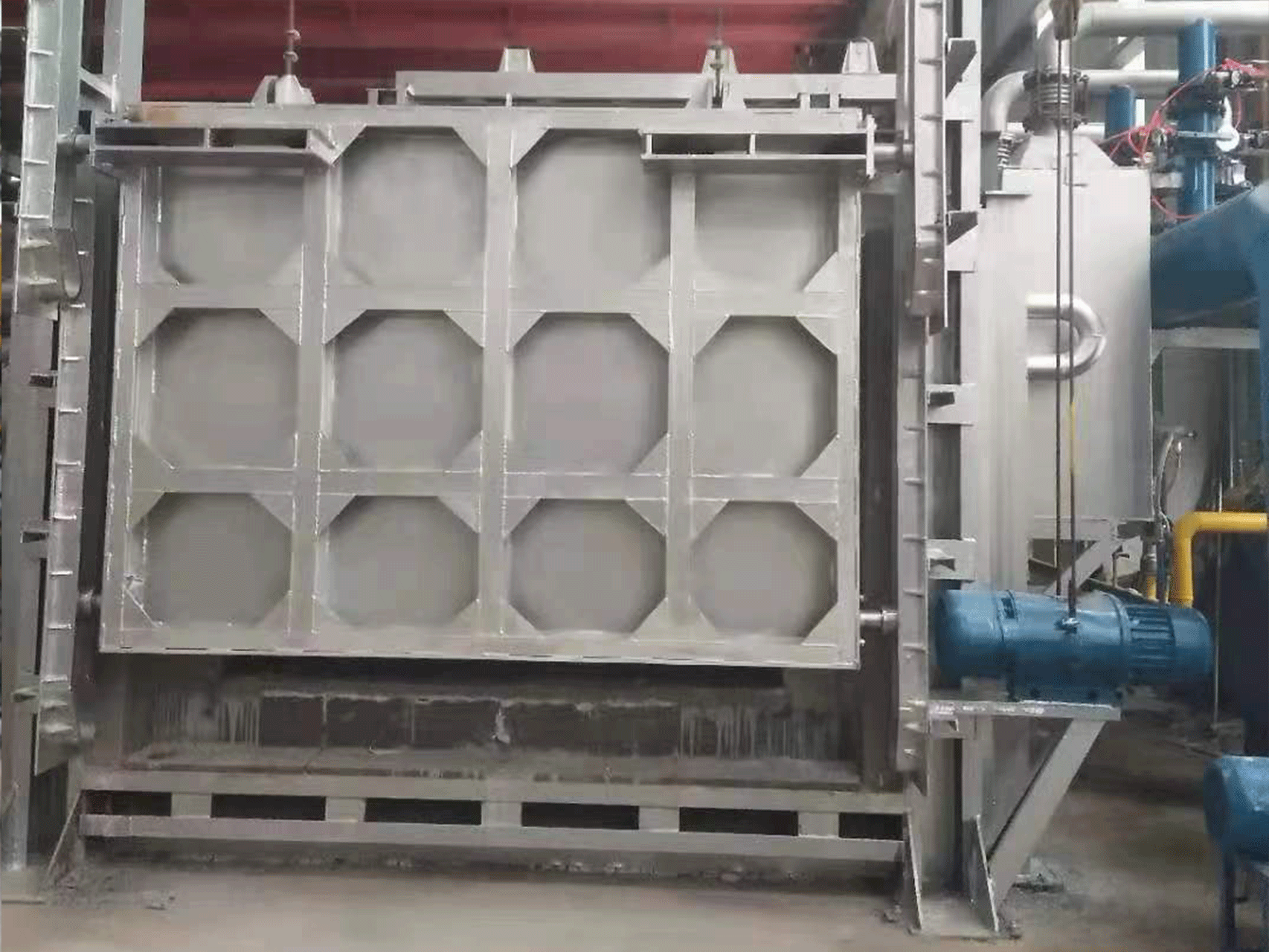

Durable Trolley Design: Uses heat-resistant trolley materials such as high-grade steel or ceramic to withstand high temperatures and ensure reliable performance.

-

Low Maintenance: Often equipped with automated cleaning and maintenance-friendly designs to reduce downtime and labor costs.

The Regenerative Trolley Type Heating Furnace is a high-performance solution for industries requiring precise, efficient, and sustainable heat treatment of metals. With its advanced regenerative process, multi-zone control, and continuous operation, it provides superior energy efficiency, reduced emissions, and consistent product quality—making it a smart investment for modern industrial operations.