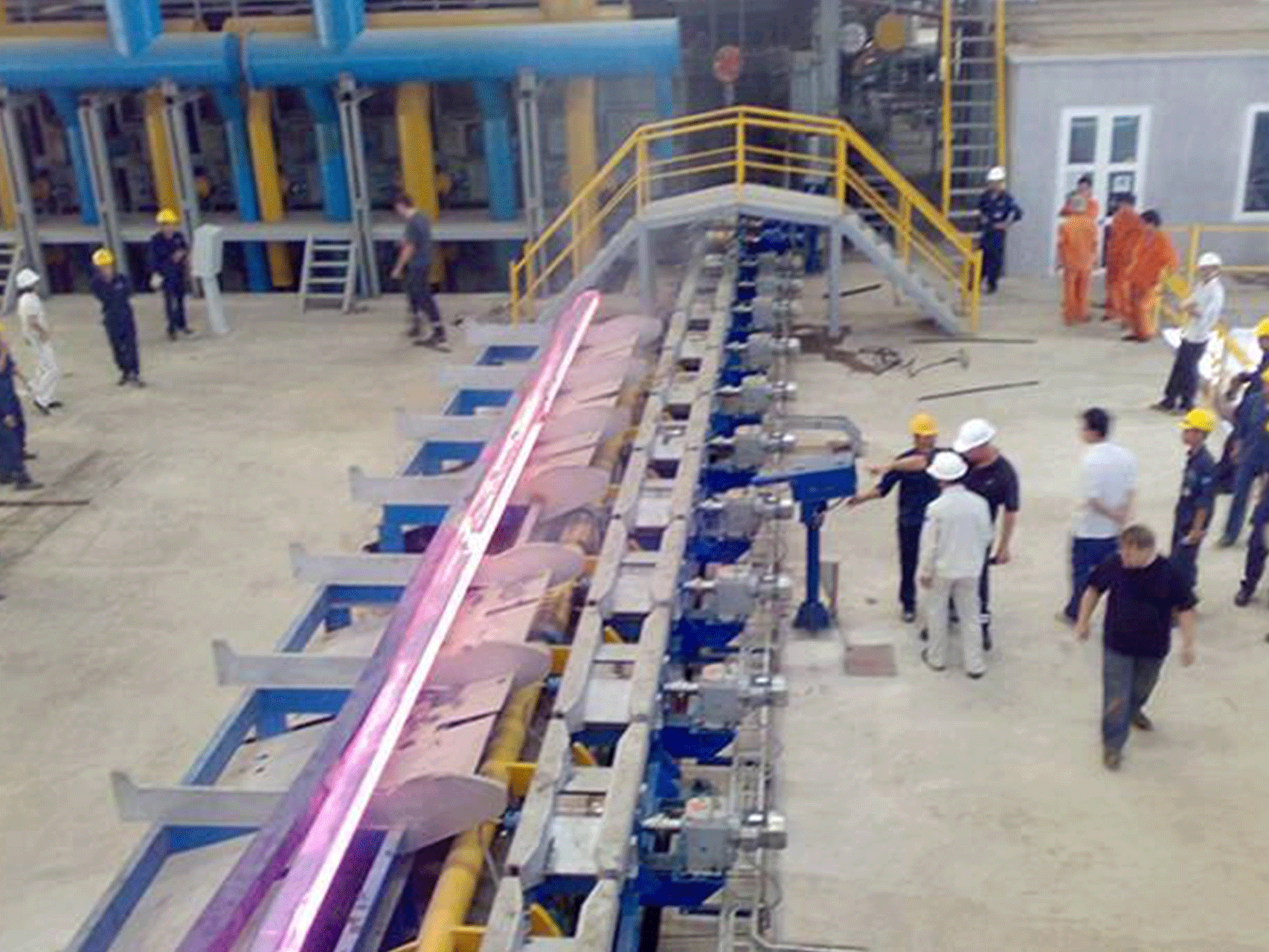

A steel heating furnace, also known as a walking beam type heating furnace, is a type of industrial furnace used for heating steel billets, slabs, and ingots to a high temperature in preparation for subsequent processing steps, such as rolling, forging, or extrusion.

The furnace consists of a series of walking beams that move the steel products through the furnace at a controlled speed. The beams are typically made of high-strength steel and are powered by hydraulic or pneumatic systems. The furnace is heated by natural gas, propane, or electricity, depending on the specific design and application. The heating process is carefully controlled to ensure that the steel products are heated to the desired temperature and held at that temperature for a precise amount of time to achieve the required metallurgical properties.

The furnace is typically operated in a batch mode, with a set of steel products being loaded onto the walking beams at one end of the furnace and removed at the other end after they have been heated to the desired temperature. The walking beam type furnace is known for its high efficiency, reliability, and consistent heating performance, making it a popular choice for steel production facilities around the world.

The furnace can be used to heat a variety of steel products, including billets, slabs, and ingots, and can achieve temperatures between 800°C to 1300°C, depending on the specific application.

Working principle: steel heating furnace

The working principle of a steel heating furnace, or walking beam type heating furnace, involves the controlled movement of steel products through a heated chamber to achieve a desired temperature.

The furnace is typically designed with a series of walking beams that support and move the steel products through the furnace chamber. The walking beams are powered by hydraulic or pneumatic systems, which control the speed and direction of the movement. The furnace is heated by natural gas, propane, or electricity, depending on the specific design and application. The heating process is carefully controlled to ensure that the steel products are heated to the desired temperature and held at that temperature for a precise amount of time to achieve the required metallurgical properties.

The temperature inside the furnace is monitored by a variety of sensors, which feed data back to a control system. The control system adjusts the heating process to ensure that the desired temperature is reached and maintained. As the steel products move through the furnace, they are exposed to the high-temperature environment and begin to heat up. The walking beams move the steel products at a controlled rate through the furnace chamber, ensuring that they are heated evenly and thoroughly.

Once the steel products have reached the desired temperature, they are typically removed from the furnace at the other end by a set of extraction rollers or a similar mechanism. The walking beams then return to the beginning of the furnace to load the next batch of steel products.

Overall, the working principle of a steel heating furnace is based on precise control of temperature, movement, and timing to ensure that steel products are heated uniformly and consistently for subsequent processing steps.

The Characteristics

Here are some of its key characteristics:

- High Efficiency: The walking beam type furnace is designed to heat steel products quickly and efficiently, using a carefully controlled heating process. This results in higher throughput and energy efficiency compared to other types of industrial furnaces.

- Precise Control: The furnace is equipped with a variety of sensors and control systems that enable precise temperature control and heating profiles. This allows for precise control over the metallurgical properties of the steel products being heated.

- Uniform Heating: The walking beam-type furnace is designed to ensure that steel products are heated uniformly and consistently throughout the chamber. This reduces the risk of hot spots or cold spots that could affect the quality of the final product.

- Reliability: The walking beam type furnace is known for its reliability and low maintenance requirements. The walking beams are typically made of high-strength steel and are designed to withstand the high temperatures and stresses of the heating process.

- Versatility: The furnace can be used to heat a variety of steel products, including billets, slabs, and ingots. It is also compatible with different heating sources, such as natural gas, propane, or electricity.