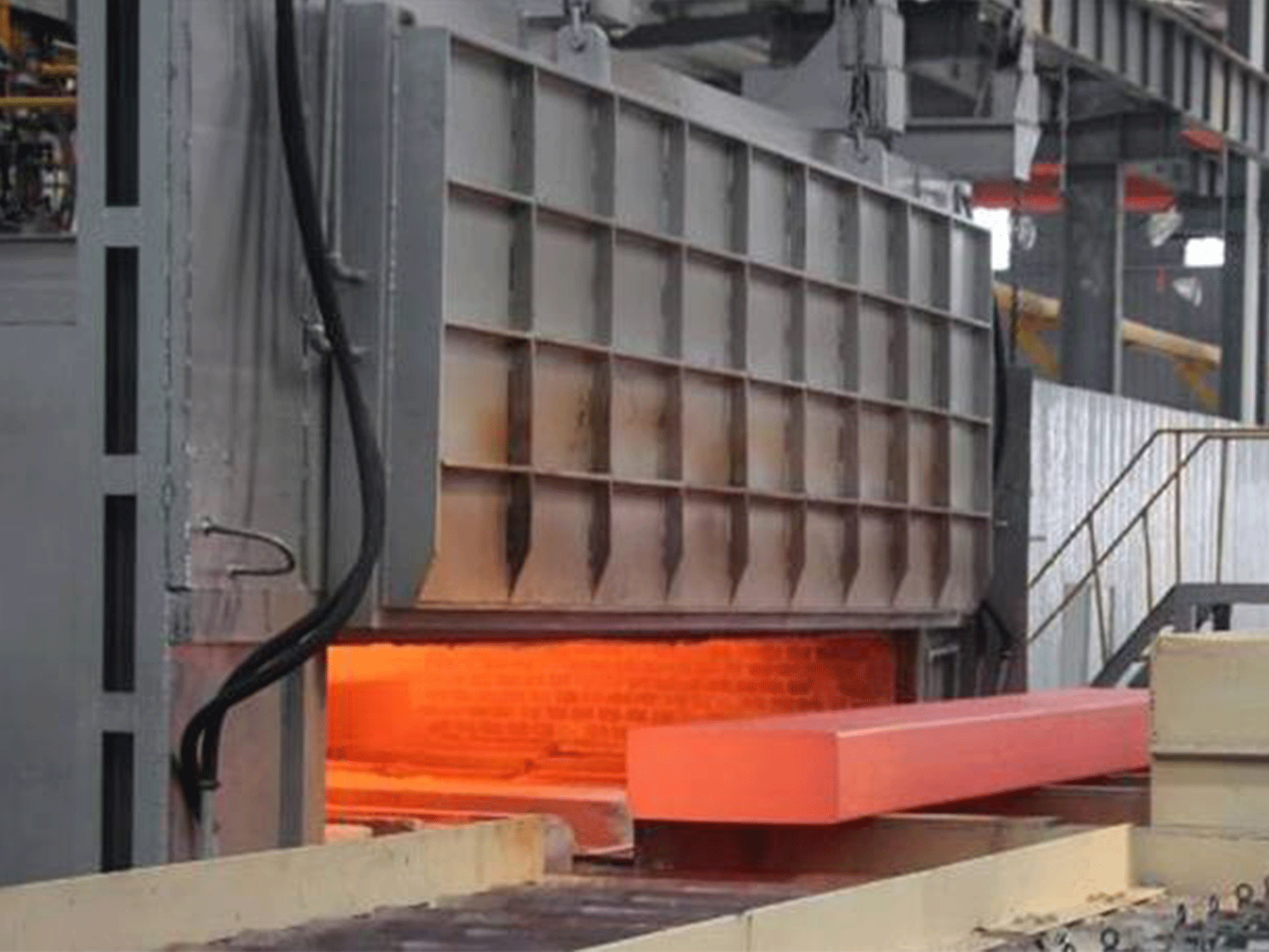

A walking beam heating furnace is an industrial furnace used to heat metal to high temperatures for metalworking processes such as forging, rolling, or other shaping techniques. The furnace is equipped with a walking beam mechanism that moves the metal through the furnace, ensuring that it is evenly heated.

The walking beam mechanism typically consists of a series of support beams or rollers that are attached to a motorized tool. As the metal is fed into the furnace, it is supported by the beams and transported through the furnace by the motorized mechanism. The metal is then discharged from the furnace and transported to the next stage of the manufacturing process.

Walking beam heating furnaces can be operated using a variety of heating methods, including gas-fired, electric resistance, or induction heating. The furnace may also incorporate a controlled atmosphere system to prevent oxidation or other chemical reactions that can occur at high temperatures.

Walking beam heating furnaces are commonly used in the manufacturing of steel, aluminum, and other metals. They are favored for their ability to provide consistent heating and minimize the risk of deformation or damage to the metal being processed. Additionally, walking beam heating furnaces can be automated, allowing for continuous operation and high throughput.

Working principle: Walking beam heating furnaces

The working principle of a walking beam heating furnace involves heating metal to high temperatures using a walking beam mechanism that moves the metal through the furnace.

The metal is fed into the furnace and supported by a series of support beams or rollers. The walking beam mechanism then moves the metal through the furnace, ensuring that it is evenly heated. As the metal is transported through the furnace, it is exposed to heat from burners or other heating elements, which can be powered by gas, electricity, or other energy sources.

To ensure consistent heating and prevent deformation or damage to the metal, the walking beam mechanism moves the metal through the furnace at a controlled speed. This speed can be adjusted based on the type of metal being processed and the desired temperature profile.

Walking beam heating furnaces may also incorporate a controlled atmosphere system to prevent oxidation or other types of chemical reactions that can occur at high temperatures. This can involve adding gases such as nitrogen, hydrogen, or argon to the furnace to create a specific atmosphere that reduces the risk of chemical reactions. Once the metal has been heated to the desired temperature, it is discharged from the furnace and transported to the next stage of the manufacturing process. Walking beam heating furnaces can be fully automated, allowing for continuous operation and high throughput, making them a popular choice for industrial metalworking applications.

The characteristics

- Consistent heating: The walking beam mechanism moves the metal through the furnace, ensuring that it is evenly heated and minimizing the risk of deformation or damage.

- High throughput: Walking beam heating furnaces are capable of processing large volumes of metal, making them ideal for high-volume manufacturing operations.

- Energy efficiency: It incorporates various energy-saving technologies such as recuperative burners or regenerative burners to increase fuel efficiency and reduce operating costs.

- Flexibility: Walking beam heating furnaces can be used to heat a wide range of metals, including steel, aluminum, and copper, making them a versatile option for a variety of metalworking applications.

- Automated operation: Walking beam heating furnaces can be fully automated, allowing for continuous operation and reducing the need for manual labor.

- Improved product quality: The consistent heating and handling provided by walking beam heating furnaces can improve product quality, with fewer defects and better mechanical properties.